REACH is transforming maintenance and repair (M&R) in intermodal and commercial trucking logistics by replacing fragmented, manual processes with a single, transparent SaaS-based platform and marketplace. It provides real-time visibility, standardization, and a single source of truth for all service and inspection events, connecting fleets, drivers, vendors, and technicians to drive efficiency, reduce downtime, and foster accountability. The platform has tracked over 19 million events and is expanding its capabilities to include predictive fleet intelligence and AI-driven vendor matching.

With over 19 million events tracked and a growing roster of partners, REACH isn’t just improving M&R visibility—it’s reshaping how logistics teams think about readiness, reliability, and respect for the people who keep freight moving.

Chapter 1: The Problem No One Wanted to Own

Before there was REACH, there was a pattern.

Drivers were frustrated. Dispatchers were overloaded. Maintenance teams were always reacting. Vendors showed up late—or not at all. And no one knew what was happening in real-time.

You could blame the system. But what system?

In intermodal logistics, there often wasn’t one. Maintenance and repair (M&R) was often conducted in spreadsheets, texts, emails, and with a lot of guesswork. No visibility. No standardization. No shared record of truth.

And yet, the wheels kept turning until they didn’t.

Chapter 2: Paul’s Journey – From Tires to Tech

To understand how REACH came to be, you need to know Paul.

In 1997, Paul stepped into the intermodal world. Over the next two decades, he would build a reputation in some of the most rugged, hands-on corners of the supply chain—at PSI (tire inflation), McGriff Industries (tire sales and service), and TRAC Intermodal.

He didn’t enter the industry with code. He entered with steel, rubber, sweat, and truth.

Later, as a consultant, he was brought in by a large intermodal fleet facing a problem. One you might recognize:

“We can’t find reliable vendors fast enough.”

There was no single dashboard. No status tracker. No visibility into repair progress or technician arrival.

Paul could have handed them a PowerPoint. Instead, he built a fix.

He joined forces with co-founders Ash and Khush. They scraped together seed money, coded a solution from scratch, and built a product.

It wasn’t called REACH yet. But the DNA was already there.

Chapter 3: REACH – The Marketplace That Changed the Conversation

Today, REACH is a mature, SaaS-based M&R marketplace serving both the intermodal and commercial trucking sectors.

But don’t mistake it for a brokerage.

REACH isn’t trying to be the service provider.

It’s not marking up repairs or negotiating costs.

It’s providing the digital infrastructure for those repairs to happen faster, cleaner, and more transparently.

“Think of REACH as a stock exchange,” Paul says. “Fleets list service needs. Vendors respond. Technicians show up. Everyone sees what’s happening when it happens.”

No more missed calls. No more guesswork. No more technicians showing up to the wrong location without the right part.

Everything—from dispatch to documentation—is visible, timestamped, and photo-backed.

Chapter 4: What ‘19 Million Events’ Really Means

One of the standout numbers on REACH’s website is “19 million service and inspection events.”

But it’s not just marketing language.

Each of those 19 million entries represents:

- A wheel seal was replaced

- A tire-mounted roadside

- A DVIR signed and verified

- A technician dispatch logged

- A photo taken and shared with stakeholders

These are not theoretical events. They are real, on-the-ground actions—each one captured with forensic precision.

The REACH platform distinguishes between two core types of workflows:

- Service Events (SE): Repairs, roadside assistance, preventive maintenance

- Equipment Inspections (EI): Pre-trip and post-trip inspections, condition reports, regulatory checks

Together, these form the heartbeat of REACH’s platform.

Chapter 5: The Quiet Power of Early Partnerships

No startup becomes a trusted industry standard without earning it. REACH earned its credibility the hard way—by delivering.

One of its earliest believers? Hub Group Trucking.

More than a client, Hub Group became a co-developer—helping shape the platform’s earliest workflows. Their partnership helped refine how inspections were logged, how service events were communicated, and how DVIRs were generated with speed and accuracy.

Then came DCLI, which used REACH first for handling unplanned maintenance—and later for powering its 24/7 roadside service RapidLink. Their public praise in recent industry forums only reinforces what REACH insiders already knew: the partnership is effective.

Add in Bridgestone North America—and their massive network of dealers like Pomps and McGriff-Best One—and you begin to see REACH’s network effect.

These companies didn’t just buy in. They helped build it.

Chapter 6: Fixing the Intermodal Paradox

If intermodal is the future of freight efficiency, it’s also the source of its own greatest inefficiencies.

The system thrives on shared assets, including chassis, containers, and trailers. However, that shared infrastructure creates unclear lines of responsibility.

- A chassis might be owned by one company, used by another, and repaired by a third.

- One driver flags an issue. But by the time the repair request reaches dispatch, the assets are in another yard.

This is the intermodal paradox: Multiple stakeholders are its strength—and also its greatest pain.

REACH doesn’t fight that complexity. It aligns it.

Its platform unites IEPs, fleets, drivers, and technicians into a single source of shared truth.

That alone saves time, costs, and friction.

Chapter 7: Centering the Technician – A Radical Move

Here’s a subtle insight most platforms miss: technicians aren’t just labor—they are the data layer.

When a repair is performed, the technician knows:

- What was wrong

- What was done

- What parts were used

- What wasn’t fixed (and why)

- And what the next issue might be

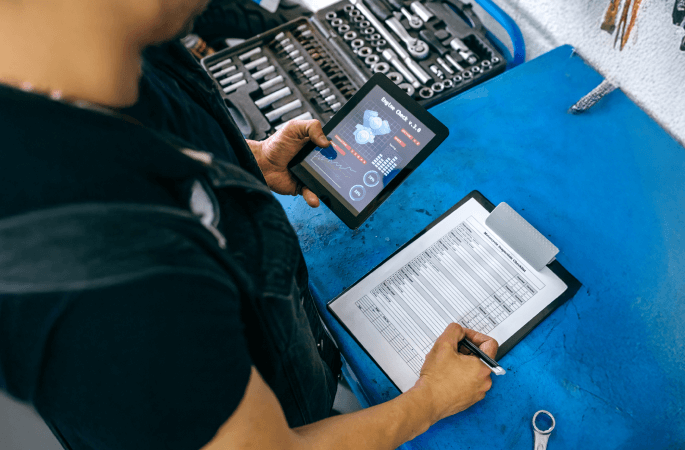

REACH treats technicians as the primary source of truth. It gives them mobile-friendly tools to:

- Accept jobs

- Record diagnostics

- Upload photos

- Track time-on-site

- And verify completion

This isn’t just for the sake of process.

It’s because every repair that’s documented reduces repeat issues, liability risks, and downstream delays.

Chapter 8: Visibility, Accountability, and the End of ‘Hopeful Logistics’

Before REACH, much of logistics operated on hope:

- “I hope the repair was done.”

- “I hope the asset was inspected.”

- “I hope the tech showed up.”

Hope is not a strategy.

REACH replaces hope with visibility.

Fleet managers, terminal supervisors, vendor partners, and even drivers can all view job progress in real-time.

- Has the technician arrived? It’s in the platform.

- Was the tire replaced or patched? There’s a photo.

- Is the unit cleared for dispatch? See the timestamp.

This level of visibility doesn’t just save time.

It builds trust—across departments, across companies, and miles.

Chapter 9: What About Commercial Trucking?

Though built in the intermodal arena, REACH isn’t staying there.

Its presence in commercial trucking is expanding—and quickly.

The same inefficiencies apply:

- Maintenance happens too late

- Dispatch lacks visibility

- Vendor quality is inconsistent

- Repairs go undocumented

REACH’s multi-tenant architecture, built to handle the complexity of intermodal, is overqualified for standard trucking use cases.

This means its growth in commercials is not a question of if but how fast.

Chapter 10: The Next Evolution – Predictive Fleet Intelligence

While REACH has largely focused on building out the provider side, it’s now doubling down on fleet intelligence tools.

Here’s what’s in the pipeline:

- Asset Tables: So fleets know exactly what’s where—and what condition it’s in

- Planned Maintenance Scheduling: Reduce breakdowns before they happen

- Condition Alerts: Notify teams when inspection patterns signal upcoming failure

These tools push REACH from a real-time reactive system into a predictive command center.

It’s the difference between putting out fires… and knowing where the smoke’s going to rise.

Chapter 11: AI That Works

“Everyone’s talking about AI,” Paul says. “We’re layering it where it adds real value.”

For REACH, AI is not an overlay—it’s an enabler.

- Suggesting the best vendor based on geography, availability, and past performance

- Auto-flagging inspection anomalies before they become safety issues

- Predicting the lifecycle of parts based on usage patterns and conditions

The goal isn’t just intelligence. It’s applied intelligence.

Chapter 12: The Real Reason REACH Works

REACH’s success isn’t about code.

It’s about listening.

- Listening to technicians when they say what slows them down

- Listening to fleet managers who need fewer blind spots

- Listening to dispatchers buried in post-its and unread emails

- Listening to drivers whose safety depends on reliable equipment

This is not Silicon Valley disruption. It’s logistics craftsmanship. Built slowly. Built carefully. Built right.

Closing Chapter: The Future of Maintenance Is Already Here

Every minute of downtime is a cost.

Every unlogged repair is a risk.

Every technician left unsupported is a missed opportunity.

And in logistics, missed opportunities scale fast.

REACH isn’t just fixing broken processes.

It’s helping the entire industry transition from a reactive to a proactive approach.

From siloed to aligned.

From paperwork to platform.

From inefficiency to intelligence.

Want to Explore What REACH Could Do for You?

Visit www.reach24.net or email explore@reach24.net

Whether you manage a national fleet, a local terminal, or vendor networks across states—REACH is built to work the way you already do. Only smarter!