Running a fleet is a daily balancing act. Trucks need to be on the road. Drivers need to be safe. Costs need to stay under control. Customers expect on-time service, and regulators expect clean records. When something goes wrong, it can affect everything at once.

An effective fleet management program gives you a structure that holds up under pressure. It connects people, tools, and vendors so information moves quickly and decisions get made without confusion. When a driver reports a problem, the right person sees it, the right vendor is called, and the repair is tracked from start to finish. When a vehicle is due for service, you know it ahead of time and can plan the work. When you look at your numbers, you can tell if you are getting better or falling behind.

In this guide, we explain the key components that make a program work in the real world. You will see how a clear data flow prevents missed issues, how strong downtime control protects revenue, and how preventive maintenance avoids road calls. You will also see how telematics and inspections lead to faster action, how to build a positive safety culture with drivers, how to manage vendors and compliance without piles of paperwork, and how to use a few simple metrics to improve each month.

If you get these pieces right, your fleet becomes easier to run. Breakdowns are less stressful. Costs are more predictable. Customers get reliable service. Most of all, your team spends less time chasing information and more time solving problems.

Clear Program Structure and Data Flow

A good fleet management program starts with knowing exactly how information moves from the road to the people who can act on it. When there is no clear process, problems get lost, repairs get delayed, and small issues turn into expensive ones.

Think of it like a chain. Every link has to be strong for the process to work.

Step 1: Collect the right information

This is the first link. Your drivers, telematics devices, inspection apps, and maintenance records are all sources of important data. That can include:

- GPS location

- Daily inspection reports (DVIR)

- Engine fault codes

- Fuel use and purchase details

- Notes from drivers about unusual noises, vibrations, or handling

If this information is scattered in different places, it is easy to miss important details.

Step 2: Organize it in one place

Once the data comes in, it needs to go into one central system where it can be sorted and prioritized. This way, urgent issues rise to the top and routine items are scheduled for later. When everyone uses the same system, there is less back-and-forth and fewer misunderstandings.

Step 3: Decide what action is needed

Not every alert needs the same response. Some issues are urgent safety risks. Others can wait until the next scheduled service. The decision-making process should be clear so that anyone in the operations team can handle a report without needing to guess.

Step 4: Act and track the results

Once the decision is made, assign the work, share the details with the vendor or mechanic, and follow the repair through to completion. Record the time it took, the cost, and the outcome. This creates a history you can use to improve in the future.

Note: If you use different systems for telematics, fuel, and maintenance, connect them through integrations or a service coordination platform like REACH. This allows information to flow automatically, cutting down on manual entry and reducing delays.

When your data flow is clear and consistent, your team can move faster, make better choices, and keep vehicles on the road instead of in the shop.

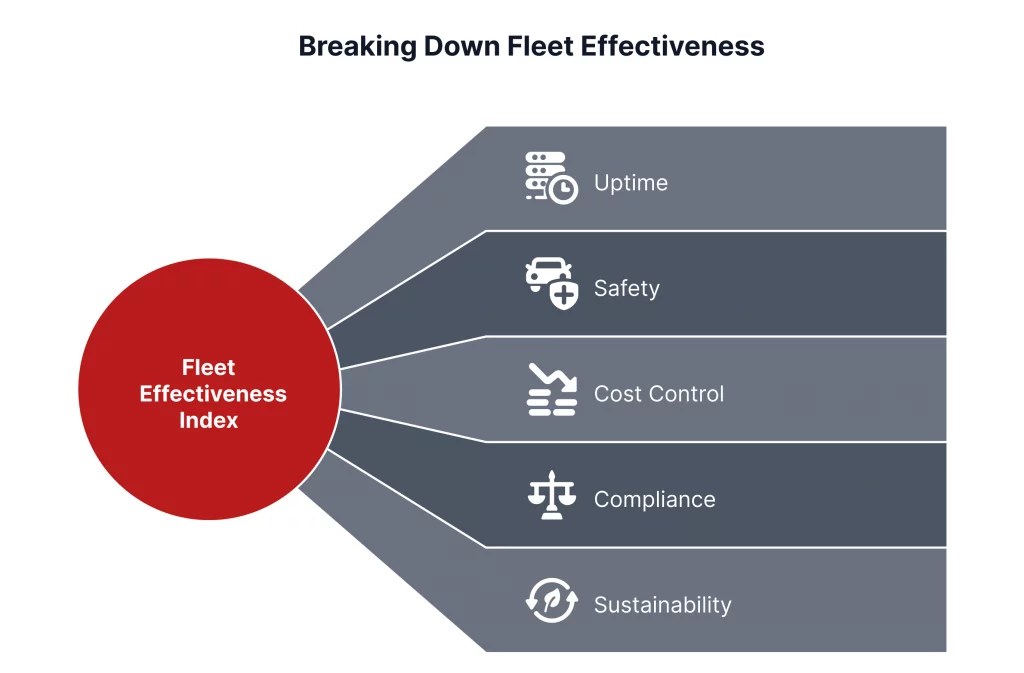

Fleet Effectiveness Index (FEI) Formula

Downtime Control (24/7 Readiness)

Downtime is when a vehicle is out of service and cannot do its job. Every hour of downtime costs money, disrupts schedules, and puts pressure on the rest of the fleet. The way you manage breakdowns often decides whether downtime is just a small inconvenience or a major business problem.

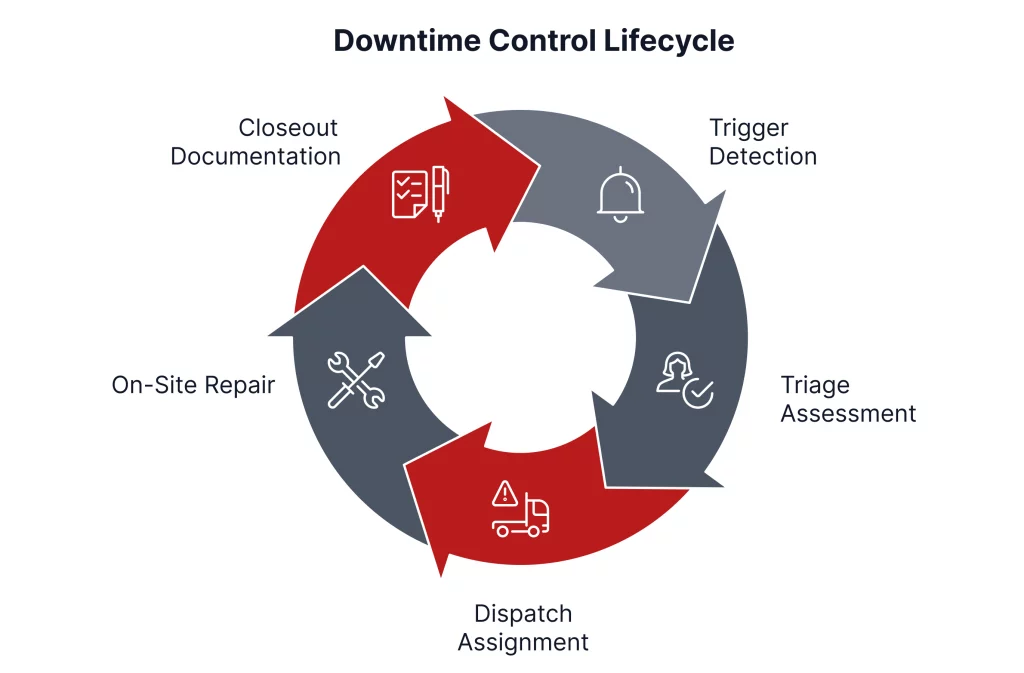

Downtime Control Lifecycle

Why 24/7 readiness matters

Breakdowns do not follow office hours. They can happen late at night, early in the morning, or far away from a home base. If your program is not ready to respond at any time, you risk delays that upset customers, spoil loads, or force expensive towing.

A simple breakdown process

Every fleet should have a clear process for handling roadside issues. Here’s an example:

- Alert – A driver reports a problem, or a fault code, or inspection shows something is wrong.

- Triage – The dispatcher or fleet manager checks the severity. Is the driver in a safe location? Is the cargo at risk? Is it a mobile repair or a tow job?

- Dispatch – Contact the right vendor or mobile repair service, share all the details, and confirm they are on the way.

- Repair – The vendor fixes the issue, or the vehicle is towed to a shop.

- Close – Record what was done, how long it took, and what it cost.

Key performance measures

- Time to Dispatch (MTTD) – How quickly you get help on the way.

- Time to Arrival (MTTA) – How quickly the repair team reaches the vehicle.

- Time to Repair (MTTR) – How quickly the vehicle is fixed and ready to work again.

- Avoided Tows – How many breakdowns are fixed on site instead of requiring a tow?

How a strong vendor network helps

If you have pre-vetted vendors in different areas, you can respond faster. This is especially important for long-haul fleets or those with routes in remote locations. Services like REACH connect you with trusted vendors at any hour, which means you do not waste time searching for help when a truck is stuck on the side of the road.

The goal

With 24/7 readiness, you cut downtime to the bare minimum. Your drivers feel supported, your customers get their deliveries on time, and your business experiences fewer delays.

Preventive Maintenance and Inspection Discipline

One of the most effective ways to keep your fleet running smoothly is to prevent problems before they happen. Preventive maintenance (often called PM) is the regular servicing and inspection of vehicles based on time, mileage, or usage hours. A disciplined PM program saves money, improves safety, and reduces stress for both drivers and managers.

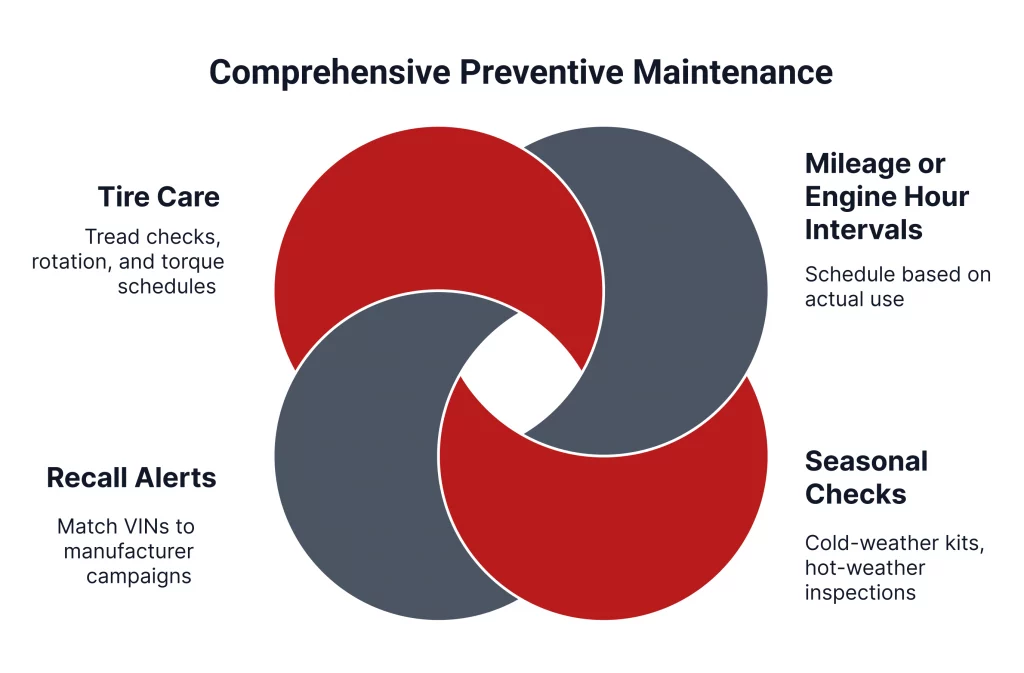

Preventive Maintenance Cycle

Why preventive maintenance matters

If you wait until something breaks, you are almost always looking at higher repair costs, longer downtime, and more disruption to schedules. Preventive maintenance helps you:

- Catch small issues early before they become expensive repairs.

- Avoid roadside breakdowns that put drivers and cargo at risk.

- Keep warranties valid by following the manufacturer’s service guidelines.

- Extend the life of your vehicles and critical components.

How to build a strong PM program

- Set clear service intervals – Base them on the type of vehicle and how it is used. Long-haul trucks may work on mileage schedules. City delivery vehicles might follow engine hours or calendar dates.

- Add seasonal checks – For example, before winter, inspect and service batteries, coolant, heating systems, and tires. Before summer, check cooling systems and air conditioning.

- Track compliance – Use a dashboard or report to see which vehicles are due, overdue, or complete.

- Standardize inspections – Use consistent checklists for drivers and mechanics so nothing is missed.

Driver inspections

Daily inspections, often logged as DVIRs (Driver Vehicle Inspection Reports), are a key part of preventive maintenance. Drivers see and hear things in the field that systems might not catch, such as unusual noises, changes in handling, or visible damage. A clear process for reporting these issues ensures they are addressed promptly.

Measure your success

Watch these indicators:

- PM compliance rate (percentage of scheduled services done on time)

- Repeat repair rate (how often the same issue comes back)

- Warranty capture (percentage of repairs covered under warranty)

When preventive maintenance and inspections are taken seriously, you avoid many of the emergencies that cause costly downtime.

Telematics and Real-Time Monitoring

Telematics is the technology that lets you see where your vehicles are, how they are being driven, and how they are performing mechanically. When used well, it gives you the information you need to take action before small problems become big ones.

What telematics can tell you

Depending on the system you use, telematics can provide:

- GPS location and route history

- Engine fault codes and performance alerts

- Speed, braking, and acceleration patterns

- Fuel consumption and idling time

- Geofencing alerts if a vehicle enters or leaves certain areas

Focus on the alerts that matter.

Telematics systems can generate a lot of data. Too many alerts can overwhelm your team and cause important issues to get lost. Focus on:

- Critical engine warnings like overheating or low oil pressure

- Brake or ABS faults

- Faults found during driver inspections (DVIR) that require urgent action

- Repeated fault codes that suggest a deeper mechanical issue

Turning data into action

Data alone will not improve your fleet. The key is connecting telematics to your service process. When a fault code or urgent alert comes in, it should automatically create a work order with all the details a vendor or mechanic needs. This means less back-and-forth and a faster fix.

Coaching drivers with safety data

If your system includes dashcams or driver behavior tracking, use that information to improve safety. Instead of only using the data to discipline drivers, treat it as a coaching tool. Showing drivers real examples of risky habits and how to avoid them can lower accident rates and insurance costs.

The benefit of real-time monitoring

With live data, you can make faster, better decisions. If a problem can be fixed during a scheduled stop instead of causing a roadside breakdown, you save time, money, and frustration.

Driver Performance and Safety Culture

Your drivers are the face of your fleet. How they operate on the road affects safety, fuel costs, maintenance needs, and customer satisfaction. A strong safety culture makes sure every driver understands what’s expected and feels responsible for keeping themselves and others safe.

Start with clear rules

Drivers should never have to guess what the company’s safety policies are. Make the rules simple and easy to remember. Cover things like:

- Speed limits and safe following distance

- Seatbelt use at all times

- No phone use while driving

- Idling limits

- How to report issues or hazards

Share these rules during onboarding, refresh them regularly, and make sure they are easy to access.

Use short, frequent training

Long training sessions are hard to remember and take drivers off the road for hours. Short, focused lessons work better. For example:

- A 10-minute refresher on winter driving

- A quick video on safe lane changes

- A checklist for secure cargo loading

Track performance with driver scorecard

A scorecard gives drivers a clear view of how they are doing. It can include:

- Number of safety violations

- Fuel efficiency

- Idle time percentage

- On-time delivery rate

- Vehicle inspection pass rate

When drivers see their scores regularly, they can take ownership of their performance.

Reward good driving

Recognition motivates. Even small rewards — like a gift card, a certificate, or a shout-out in a team meeting — can encourage safe, efficient driving.

Have a plan for incidents

When something goes wrong:

- Collect all the facts — inspection reports, dashcam footage, and statements.

- Review what happened and why.

- Take steps to prevent it from happening again through training or process changes.

The goal

A safety-focused culture protects drivers, reduces accidents, and builds trust with customers. It also lowers costs by cutting down on repairs, insurance claims, and delays.

Vendor and Compliance Management

A fleet is only as reliable as the people and services it depends on. Strong vendor relationships keep repairs quick and consistent, while good compliance practices keep you ready for inspections without the stress.

Choosing and managing vendors

Vendors are your repair shops, towing providers, and mobile technicians. Choosing the right ones and keeping them accountable is critical.

- Look for coverage – Can they handle the regions where your vehicles operate?

- Check capabilities – Do they have the skills, equipment, and certifications for your fleet’s needs?

- Test responsiveness – How quickly do they reply to a service call?

- Review pricing – Make sure rates are clear and fair.

Once you select vendors, set Service Level Agreements (SLAs), which are written commitments on how fast they respond, how they communicate during repairs, and the quality standards they follow. Review their performance regularly so you can address issues early.

Staying compliant without the paperwork headache

Fleet compliance means following rules for vehicle safety, driver qualifications, inspections, and reporting. The simplest way to manage it is to keep everything digital.

- Store all inspection records, repair logs, and driver certifications in one place.

- Use alerts to flag when inspections are due or documents are about to expire.

- Keep an “audit kit” – a digital folder with key compliance documents ready to send if an inspector asks.

Why this matters

When vendors know your expectations and you can find any compliance record in minutes, you save time, avoid fines, and keep your fleet moving. It also means you can focus on running operations instead of chasing down paperwork or calling multiple shops.

Continuous Improvement and KPI Tracking

Even a strong fleet management program can get better. The way to keep improving is to measure what matters, look at the results regularly, and make changes where they will have the most impact.

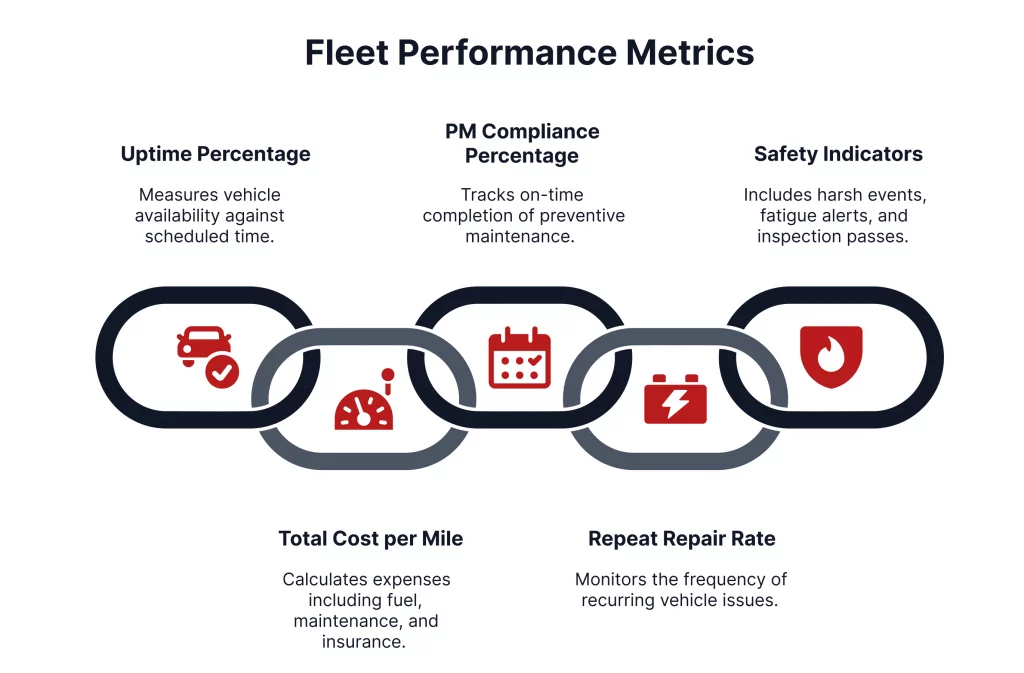

Top KPIs to Track

Start with a few key metrics.

Tracking too many numbers can be overwhelming. Focus on the ones that tell you how well your fleet is running:

- Uptime percentage – How often vehicles are available for work.

- Total cost per mile – All costs (fuel, maintenance, insurance, admin) divided by miles driven.

- Preventive maintenance (PM) compliance rate – How often scheduled maintenance is done on time.

- Repeat repair rate – How often the same issue comes back.

- Safety indicators – Harsh braking events, inspection pass rate, fatigue alerts.

Review and compare

Look at these numbers each month or quarter. Compare them to your past performance and similar vehicles or routes.

- If one vehicle type has lower costs, consider buying more of that model.

- If certain routes show higher breakdowns, review the conditions and driving patterns.

- If downtime is rising, investigate vendor performance or maintenance delays.

Act on what you learn.

Metrics are only useful if you act on them. That could mean adjusting service intervals, replacing older vehicles sooner, adding training for drivers, or negotiating better vendor terms.

Why it works

When you track and improve a few important numbers consistently, you make smarter decisions. Over time, this builds a fleet that is more reliable, more efficient, and easier to manage.

Building a Program That Delivers Every Day

An effective fleet management program is not just a checklist of tools and processes. It is a system that keeps vehicles on the road, drivers safe, and costs under control, even when something unexpected happens.

The most successful programs combine good planning, reliable partners, clear communication, and smart use of data. They have processes that work during normal operations and hold up during emergencies.

If you focus on the key components we’ve covered — from preventive maintenance and vendor management to compliance, downtime control, and KPI tracking — you create a program that is ready for anything.

And remember, uptime is where the real results show. That is why having a trusted 24/7 breakdown response partner like REACH can make all the difference. The faster you can get vehicles back on the road, the more you protect revenue, customer trust, and safety.

Cut your downtime now! Coordinate repairs with REACH and keep your fleet moving, day or night.