It is 7:15 on a Monday morning, and the dispatch office is already buzzing. Phones ring, drivers check in, and a worried customer calls asking where their delivery is. The fleet manager glances at two screens: one displays yesterday’s inspection notes, and the other shows a spreadsheet of scheduled routes. What he really needs is simple: to know where his vehicles are right now, which ones are road-ready, and which ones need service. Without that visibility, every decision feels like a gamble.

This is where fleet management tracking systems have transformed the industry. What began as basic GPS devices that plotted dots on a map has evolved into platforms that combine live location, compliance tracking, driver safety, and uptime management. By 2026, these systems will no longer be optional extras. They have become the backbone of how fleets remain efficient, safe, and profitable in a world where customer expectations and regulatory demands continue to rise.

This article explains what a fleet management tracking system is, why live location remains its foundation, and how safety, compliance, and uptime come together to deliver measurable ROI. It also demonstrates why REACH is the system of choice for fleets seeking integration without complexity.

Key Takeaways

- Fleet management tracking systems go beyond GPS location to cover compliance, safety, and uptime.

- Live location remains the foundation for dispatch efficiency and customer trust.

- Integrated systems reduce downtime by connecting inspections directly to service workflows.

- Compliance becomes routine with audit-ready records tied to GPS data, ensuring accuracy and transparency.

- REACH sets the modern standard by delivering practical integration and measurable ROI.

What is a Fleet Management Tracking System?

A fleet management tracking system is more than a GPS device. It is a comprehensive ecosystem that integrates hardware installed in vehicles with a digital platform, enabling managers to monitor operations. Together, they create a live picture of the fleet’s health, location, and readiness.

At the hardware level, devices collect signals from satellites and transmit data about vehicle movement and status. This may be through plug-and-play OBD units, hardwired trackers for long-term use, or solar-powered devices for trailers and containers. On their own, these devices provide only raw location data.

The real value is realized when this data is integrated into a management platform. The platform organizes it into dashboards, alerts, and workflows. Instead of simply knowing that a truck is moving, managers can see if it has cleared inspections, whether defects have been logged, and if it is scheduled for service. Dispatchers can reroute vehicles with confidence, service teams can prepare repairs more efficiently, and compliance managers can ensure their records are ready for audits.

The distinction between a device and a system is critical. Devices track. Systems manage. In 2026, fleets cannot afford to settle for tracking alone. They need integrated systems that connect location to safety, compliance, and service. That is how visibility becomes action.

Live Location — Why Visibility Comes First

Live location is the foundation of any fleet tracking system. Without it, everything else becomes more challenging: dispatchers cannot reroute vehicles in real-time, managers cannot confirm progress, and customers are left in the dark. In logistics, every minute matters, and live visibility turns uncertainty into control.

Why Real-Time Location Matters

Real-time tracking allows managers to see exactly where every vehicle is and what it is doing. This matters when deliveries run behind schedule, traffic delays accumulate, or urgent jobs arise at the last minute. Instead of guessing, dispatchers can make informed decisions that keep schedules on track and ensure customer satisfaction.

The Dispatch Advantage

Imagine a truck stuck in traffic on the edge of a city. Without live tracking, the dispatcher can only wait and hope the delivery is not delayed. With live tracking, the dispatcher can instantly identify the issue, reroute an available vehicle nearby, and still meet the customer’s deadline. One decision, made possible by visibility, preserves both revenue and trust.

Customer Confidence

Shippers want transparency. They want to know not only that a truck has left the yard but also when it will arrive. Live location provides that assurance. When customers receive accurate updates backed by real-time data, they gain confidence that their deliveries are reliable and their fleet partner is trustworthy.

From Data to Insight with REACH

Live location is not just a dot on a map. In REACH, location data is tied directly to compliance and service workflows. Managers do not just see where a truck is; they also know if it is road-ready, compliant, and available for its next assignment. This is the difference between tracking for awareness and tracking for action.

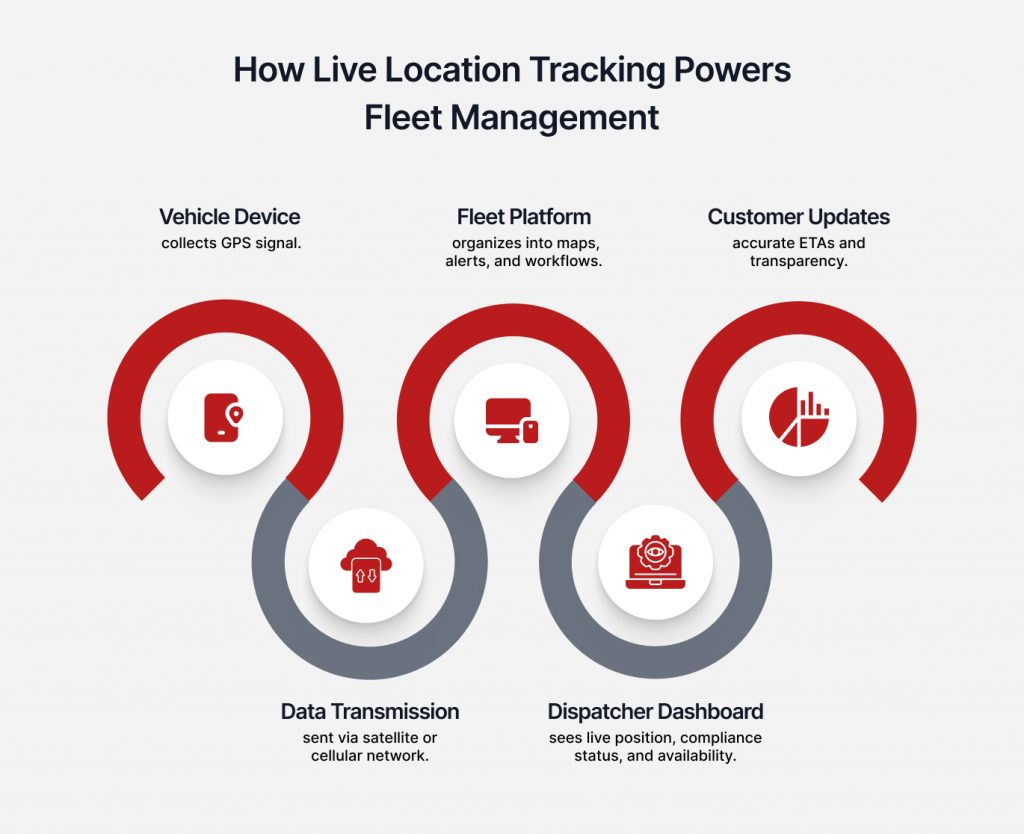

How Live Location Tracking Works

Safety and Compliance Beyond the Map

Live location is powerful, but a true fleet management tracking system does much more than show where a vehicle is. In 2026, the best systems extend into safety and compliance, two areas that directly affect operational stability and customer trust.

Protecting Drivers and Fleets

Safety on the road is about more than defensive driving. Fleets need accountability and evidence when incidents occur. With tracking systems, managers can confirm routes, validate stops, and defend drivers against false claims. A recorded trail of location and inspection data can be the difference between a costly dispute and a quick resolution.

Compliance Built Into Daily Operations

Regulations are strict, and falling behind is expensive. A fleet might have accurate GPS data, but if inspections are tracked separately, managers still face the risk of penalties and downtime. An integrated system ties GPS directly to inspection logs and DVIRs. Each vehicle profile carries not only its location but also its compliance status. Audits become faster and less stressful because every record is digital, organized, and ready for review.

A Real-World Example

Consider a vehicle that has been pulled over for a roadside inspection. In a disconnected setup, the driver may scramble to provide paperwork or proof of inspection. With an integrated tracking system, the compliance record is tied directly to the GPS profile. The inspector can quickly confirm road readiness, the driver avoids unnecessary delays, and the fleet moves on without disruption.

REACH and Compliance-First Design

This is where REACH sets itself apart. Safety and compliance are not treated as add-ons; they are integral to our operations. Every GPS update connects to inspections, service workflows, and audit-ready reports. Fleets using REACH do not just know where vehicles are. They know those vehicles are safe, compliant, and ready for work. This confidence changes the way fleets operate, shifting compliance from a liability to a daily strength.

Uptime and ROI — Tracking’s Hidden Value

Fleet managers often view tracking systems as visibility tools, but their hidden strength lies in how they protect uptime. Every hour a vehicle is unavailable costs money. In some fleets, even a single truck sitting idle can mean thousands of dollars in lost revenue. A well-designed tracking system prevents this by connecting inspections to service workflows and shortening the repair cycle.

Turning Inspections Into Action

Traditionally, when a driver finds a defect during an inspection, it can take hours for that information to reach the service team. Vehicles wait while paperwork is processed, and repairs are delayed. With an integrated tracking system, that defect is logged instantly, tied to the vehicle’s GPS profile, and sent directly to the service dashboard. Managers are aware of the issue the moment it is reported and can schedule repairs promptly.

Predictable Downtime, Stronger Planning

By reducing lag between defect reporting and repair, fleets make downtime more predictable. Instead of trucks being sidelined unexpectedly, service events are planned, tracked, and resolved faster. This means dispatchers can adjust schedules with confidence and customers experience fewer disruptions.

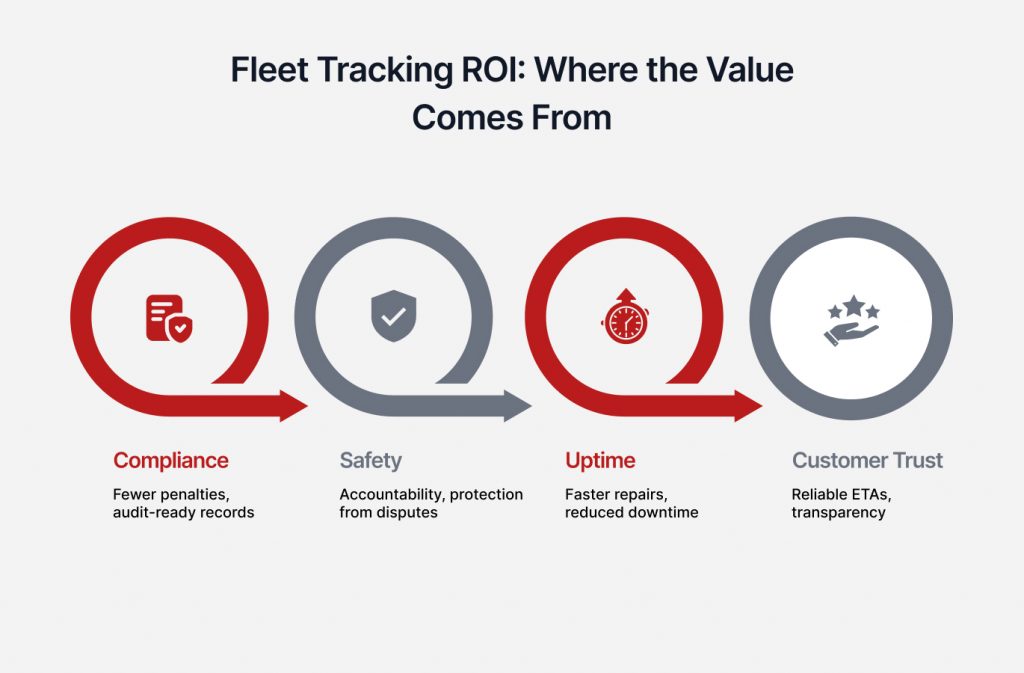

ROI in Real Terms

Shorter downtime leads to measurable savings. Fleets cut back on overtime, avoid the revenue loss of idle vehicles, and reduce penalties from missed deadlines. When combined with compliance protection and customer trust, the financial impact of a tracking system becomes clear. It is not just a tool for seeing vehicles on a map. It is a system that pays for itself many times over.

Why REACH Delivers More

With REACH, uptime is built into the design. Inspections trigger service events automatically, repairs are tracked in real time, and managers always know when vehicles will return to operation. By converting GPS data into workflows, REACH enables fleets to reduce downtime, protect revenue, and enhance reliability without adding complexity.

Fleet Tracking ROI

Why REACH Defines Modern Fleet Tracking

Not all tracking systems are created equal. Many focus only on maps, while others add so many features that fleets struggle to adopt them. What fleets need in 2026 is a system that strikes a balance between power and practicality. This is where REACH sets the standard.

Hardware Flexibility

REACH does not lock fleets into a single device. Whether the operation relies on plug-and-play OBD units, hardwired trackers for high-value assets, or solar-powered devices for trailers, REACH integrates them all into one platform. This flexibility ensures fleets can choose hardware that fits their needs and budgets without losing visibility or control.

Compliance First

In logistics, compliance is non-negotiable. REACH ties GPS data directly to inspections and DVIR records. Every update is linked to compliance workflows, automatically creating audit-ready documentation. This design reduces the stress of inspections and eliminates the risk of overlooked records.

Service Digitization and Uptime

Downtime is the cost that hurts most fleets the most. REACH addresses it head-on. Defects logged during inspections flow instantly into service events. Managers track progress in real time, shortening the repair cycle and returning vehicles to operation faster. Uptime is protected because service is no longer an afterthought.

Clear Dashboards for Managers and Customers

Integration is valuable only if the information is easy to use and understand. REACH dashboards present the location, service status, and compliance readiness in a single view. Dispatchers see which vehicles are available, service managers know what repairs are in progress, and customers receive accurate ETAs supported by real-time data.

Practical Innovation

Other systems overload fleets with features that sound impressive but add little value. REACH focuses on outcomes: compliance confidence, reduced downtime, and stronger customer trust. This approach ensures fast adoption and immediate ROI without unnecessary complexity.

The Modern Standard

In 2026, a fleet management tracking system is not about watching dots on a screen. It is about integrating live location, compliance, safety, and service into one solution. REACH defines that modern standard by turning GPS data into actionable workflows that protect uptime and build trust.

Conclusion: From Maps to Management

Fleet tracking has evolved significantly from its origins in simple GPS dots on a map. In 2026, a true fleet management tracking system is a complete operational tool. It delivers live location for dispatch and customer confidence, integrates safety and compliance into daily workflows, and protects uptime by turning inspections into fast service actions.

The fleets that thrive are those that treat tracking not as an accessory, but as a foundation for visibility, accountability, and reliability. By connecting data across compliance, service, and customer updates, tracking systems are no longer just about knowing where vehicles are; they are also about understanding the broader context of vehicle operations. They are about making every mile safer, every audit smoother, and every delivery more reliable.

REACH embodies this shift. It integrates hardware flexibility, compliance-first design, and service digitization into a platform that transforms data into action. For fleets under pressure to do more with fewer resources, REACH defines what a modern tracking system should be: practical, reliable, and ROI-driven.

Frequently Asked Questions (FAQs)

-

What is a fleet management tracking system?

A fleet management tracking system combines GPS devices with a digital platform that monitors location, compliance, safety, and service readiness. It provides managers with a comprehensive, real-time view of fleet operations.

-

How does a fleet tracking system work?

Devices installed in vehicles capture GPS signals and transmit data via satellite or cellular networks. This data flows into a platform that displays live maps, compliance records, and service alerts for dispatchers and managers.

-

What are the benefits of fleet tracking systems?

Benefits include live location visibility, shorter downtime, stronger compliance confidence, safer operations, and more reliable customer service. These advantages directly improve ROI.

-

How do tracking systems improve safety and compliance?

By linking GPS data to inspection logs and DVIRs, tracking systems generate digital compliance records, safeguarding drivers during disputes. Managers can prove road readiness and respond quickly to safety issues.

-

Why is uptime important in fleet tracking?

Every hour a vehicle is unavailable costs money. Integrated tracking systems reduce downtime by automatically converting inspections into service events and tracking repairs in real-time.

-

What makes REACH different from other tracking systems?

REACH is hardware-agnostic, compliance-first, and designed to reduce downtime. It transforms raw GPS data into actionable workflows that improve safety, compliance, uptime, and customer trust.