Every fleet manager knows that downtime is expensive. A single truck out of service can cost thousands of dollars each day in lost revenue, overtime pay, and missed deliveries. When breakdowns happen unexpectedly, they not only disrupt schedules but also damage customer trust and create compliance risks.

The best way to avoid these losses is through preventative maintenance services. Instead of waiting for vehicles to fail, fleets take a proactive approach by inspecting, servicing, and repairing equipment on a scheduled basis. This keeps vehicles road-ready, extends their lifespan, and drastically reduces surprise breakdowns.

In this article, we explain exactly how preventative maintenance services reduce fleet downtime. You will see what these services include, how they work in practice, and the steps fleets can take to build a preventative program that works. We will also demonstrate how REACH simplifies preventive maintenance by automatically converting inspections into service events.

Key Takeaways

- Downtime costs fleets thousands of dollars per vehicle each day.

- Preventative maintenance reduces downtime by addressing issues before breakdowns occur.

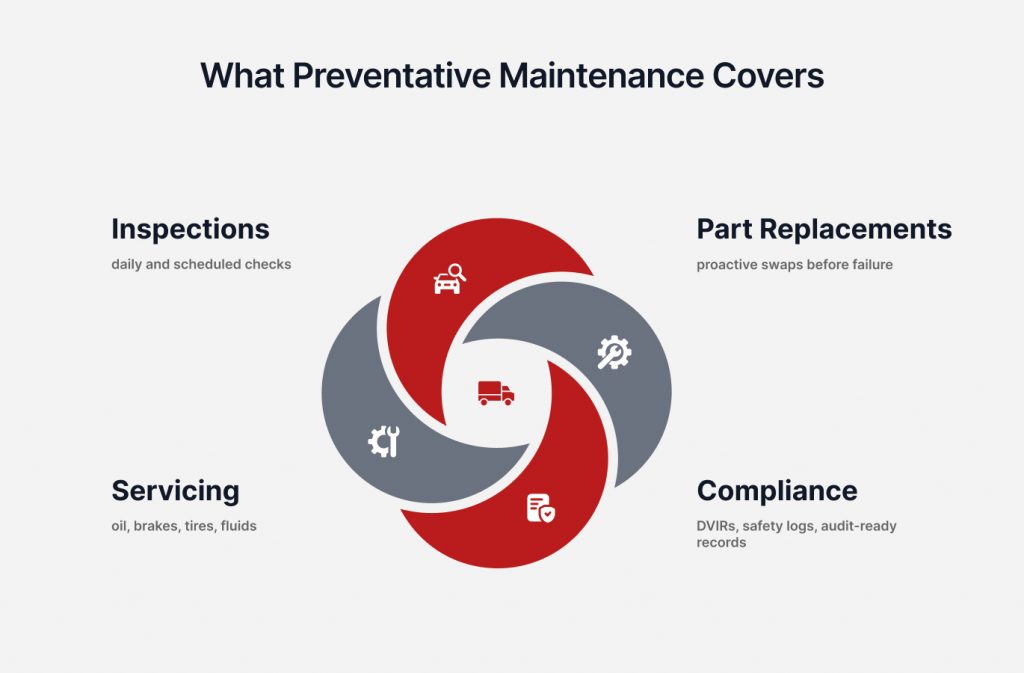

- Core services include inspections, scheduled servicing, proactive part replacements, and compliance checks.

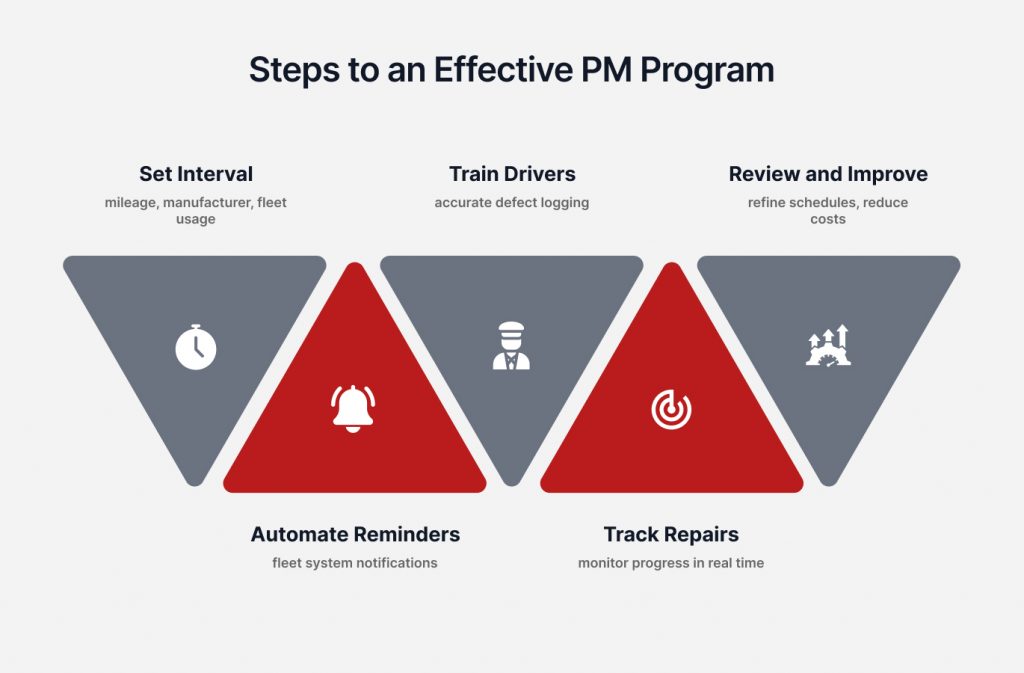

- A structured program sets intervals, automates reminders, trains drivers, and tracks repairs in real time.

- REACH simplifies preventative maintenance with digital workflows, service automation, and audit-ready compliance records.

- Fleets that use REACH for preventative maintenance protect uptime, reduce costs, and strengthen customer trust.

Why Downtime Hurts Fleets

Before understanding how preventive maintenance reduces downtime, it is essential to understand why downtime is such a critical issue.

The Cost of Idle Vehicles

Industry studies show that downtime costs fleets anywhere from hundreds to thousands of dollars per vehicle, per day. The cost includes lost deliveries, wasted driver hours, and additional repair expenses. For smaller fleets, even one vehicle out of service can throw schedules into chaos.

Impact on Customer Trust

Customers expect deliveries on time. When a vehicle breaks down and shipments are delayed, it creates frustration and weakens trust. Over time, unreliable performance can lead to fleets losing contracts and struggling to retain business.

Compliance Risks

Breakdowns often lead to missed inspections or incomplete records. If a vehicle is pulled over and compliance documentation is not up to date, fleets risk fines, failed audits, or having vehicles pulled off the road.

Why Reactive Maintenance Falls Short

Reactive maintenance refers to fixing vehicles only after they have broken down. While it addresses the immediate problem, it leads to unpredictable downtime, higher repair costs, and lost opportunities. Preventative maintenance services solve this by identifying issues early and planning services before breakdowns occur.

What Preventative Maintenance Services Include

Preventative maintenance (PM) services are designed to keep vehicles in top condition and reduce the risk of unexpected failures. They go beyond quick fixes by building a structured schedule of inspections, servicing, and part replacements that protect uptime and improve safety.

Regular Inspections

Daily walkarounds, weekly checks, and scheduled inspections help identify problems early. Drivers and managers can log defects before they become serious, ensuring issues are addressed before vehicles are dispatched.

Scheduled Servicing

Routine servicing keeps essential systems functioning smoothly. This includes oil changes, fluid checks, brake servicing, tire rotations, and battery testing. By following manufacturer and industry-recommended intervals, fleets avoid breakdowns caused by wear and tear.

Proactive Part Replacements

Preventative maintenance is not only about fixing what is broken; it is also about preventing future issues. It also involves replacing parts before they fail. Common examples include belts, hoses, filters, and tires. Proactive replacements reduce the risk of sudden breakdowns on the road.

Compliance-Related Maintenance

PM services also cover compliance requirements such as DVIRs and safety checks. Inspections are tied to vehicle profiles, creating digital records that are ready for audit and review. This reduces the risk of fines and ensures that vehicles remain legally roadworthy.

The Bigger Picture

When all of these services are combined into a preventative program, fleets gain consistency. Vehicles are serviced on time, defects are addressed promptly, and compliance records are always available. The result is fewer surprises, less downtime, and stronger customer confidence.

Core Elements of Preventative Maintenance Services

How Preventative Maintenance Reduces Fleet Downtime

Preventative maintenance works because it transforms the way fleets approach repairs. Instead of reacting after breakdowns occur, managers use structured services to stay ahead of problems. This reduces downtime by keeping vehicles road-ready and minimizing the chance of sudden failures.

Step 1: Identify Issues Early Through Inspections

Regular inspections are the first line of defense. Drivers log defects during walkarounds, and managers review them before dispatch. A minor issue, such as a worn tire or fluid leak, can be identified and addressed immediately. Addressing these problems early prevents them from becoming major breakdowns that sideline vehicles for days.

Step 2: Schedule Repairs Before Breakdowns

With preventative maintenance, repairs are handled on a planned schedule. Vehicles are serviced during low-demand periods, minimizing disruptions. Instead of losing revenue to unexpected downtime, fleets maintain control by deciding when vehicles are sent to the shop.

Step 3: Keep Vehicles Compliant and Road Ready

Compliance failures can lead to vehicles being pulled off the road. By tying inspections and servicing to compliance requirements, preventative maintenance ensures fleets have complete records. Vehicles are always audit-ready, which reduces downtime caused by regulatory issues.

Step 4: Extend Vehicle Lifespan and Reduce Surprise Costs

Routine servicing and proactive replacement of parts extend the lifespan of fleet assets. Engines run more efficiently, brakes last longer, and vehicles perform better over time. This reduces the frequency of unexpected failures and keeps the fleet operational.

A Real-World Example

A regional delivery company, operating 80 trucks, shifted from reactive to preventive maintenance after experiencing frequent breakdowns. Within the first year, unplanned downtime dropped by 30 percent. Vehicles were returned to service faster, customer complaints decreased, and overall maintenance costs were lower because issues were identified and addressed before they escalated into expensive repairs.

Building a Preventative Maintenance Program

Preventative maintenance only works when it is structured and consistent. A clear program ensures that inspections, servicing, and repairs happen on schedule and that managers can track progress at every step. Building such a program requires planning, the right tools, and team alignment.

Set Service Intervals

The first step is to establish service intervals based on the manufacturer’s recommendations, vehicle usage, and fleet priorities. High-mileage vehicles may need more frequent servicing, while others can follow standard schedules. Setting intervals ensures that maintenance becomes a routine rather than a reactive process.

Use Technology to Automate Reminders

Fleet management systems eliminate the guesswork from scheduling. They can automatically generate reminders when a vehicle is due for an inspection, oil change, or compliance check. This prevents missed servicing and ensures consistency across the entire fleet.

Train Drivers to Log Defects

Drivers are the eyes and ears of preventative maintenance. Training them to log defects accurately during walkarounds ensures issues are flagged quickly. When drivers understand that inspections protect their safety and reduce the likelihood of breakdowns, they become active participants in the program.

Track Repair Completion in Real Time

Repairs should not disappear into paperwork. Fleet systems allow managers to track service requests from creation to completion. Managers see what is pending, what is in progress, and when vehicles will return to operation. This level of visibility reduces downtime and builds accountability within the team.

Review and Improve Regularly

Preventative maintenance programs should evolve with fleet needs. Managers can review downtime metrics, repair costs, and inspection trends to refine schedules and processes. Continuous improvement ensures the program delivers maximum ROI over time.

How to Build a Preventative Maintenance Program

Why REACH Makes Preventative Maintenance Simple

Preventative maintenance can feel overwhelming if fleets rely on paper logs, manual scheduling, and disconnected systems. This is where REACH transforms the process. It automatically turns inspections into service events, digitizes repair workflows, and keeps managers informed in real-time. The result is preventative maintenance that actually reduces downtime, rather than creating extra work.

Inspections That Trigger Service Events

In REACH, every inspection is logged digitally. If a driver records a defect during a walkaround, it is not stored in a file and is not waiting for manual entry. The system creates a service request instantly, ensuring the issue is flagged for repair without delay.

Real-Time Repair Tracking

Once service events are created, REACH tracks their progress from start to finish. Managers view which repairs are pending, which are in progress, and when vehicles will be returned to the road. This visibility eliminates guesswork and keeps downtime predictable.

Compliance Built Into the Workflow

Every inspection and repair logged in REACH is tied to the vehicle’s profile. When regulators request proof of compliance, fleets can provide digital, timestamped records in seconds. Compliance becomes an integral part of daily operations, rather than a stress point during audits.

Hardware Agnostic Flexibility

REACH integrates with a wide range of hardware, from plug-and-play OBD devices to solar-powered trackers. Fleets can choose the devices that suit their needs and still benefit from the same preventative maintenance workflows.

ROI That Fleets Can See

By reducing downtime, preventing compliance penalties, and protecting vehicle lifespan, REACH delivers measurable savings. Fleets that adopt REACH for preventative maintenance see not just smoother operations but also a clear return on investment.

Why It Matters

Preventative maintenance only works if it is consistent. REACH ensures consistency by digitizing every step, from inspections to repairs. This makes preventative maintenance simple, repeatable, and effective for fleets of all sizes.

Prevent Downtime Before It Starts

Downtime is one of the biggest challenges fleets face, as it costs money, disrupts schedules, and erodes customer trust. Reactive maintenance addresses problems after they happen, but it leaves fleets vulnerable to unexpected breakdowns and higher costs. Preventative maintenance services take a proactive approach, identifying issues early, scheduling services before failures occur, and keeping vehicles road-ready.

When structured into a clear program, preventative maintenance reduces downtime, extends vehicle lifespan, and ensures compliance confidence. It transforms maintenance from a source of stress into a strategic advantage.

REACH makes preventative maintenance simple. By digitizing inspections, automatically triggering service events, and tracking repairs in real-time, it eliminates delays and improves consistency. Fleets that adopt REACH not only reduce downtime but also gain reliability, compliance readiness, and long-term ROI.

Preventative maintenance is no longer optional. For fleets that want to stay competitive in 2026 and beyond, it is the only way to keep vehicles moving and customers satisfied.

Frequently Asked Questions (FAQs)

-

What is preventative maintenance for fleets?

Preventative maintenance is a proactive approach that involves regularly inspecting, servicing, and repairing vehicles according to a scheduled plan. It helps identify issues early and prevents breakdowns that cause unexpected downtime.

-

How does preventative maintenance reduce downtime?

By catching problems before they become major failures, preventative maintenance ensures vehicles are serviced during planned intervals. This reduces surprise breakdowns, keeps vehicles road-ready, and shortens repair cycles.

-

What services are included in preventative maintenance?

Preventative maintenance typically includes inspections, oil and fluid changes, tire and brake servicing, proactive part replacements, and compliance-related checks such as DVIRs and safety logs.

-

How often should preventative maintenance be scheduled?

The frequency depends on manufacturer recommendations, mileage, and usage patterns. High-mileage or heavy-duty vehicles may need more frequent servicing, while others can follow standard schedules.

-

What is the difference between preventative and reactive maintenance?

Reactive maintenance fixes vehicles only after a breakdown occurs, leading to unpredictable downtime and higher costs. Preventative maintenance avoids these risks by addressing issues before they cause failures.

-

How does REACH support preventative maintenance?

REACH digitizes inspections, automatically creates service requests when defects are logged, tracks repairs in real-time, and ties everything to compliance records. This simplifies preventative maintenance and reduces downtime.