The first thing you notice is the movement. Towering cranes glide overhead, lifting steel containers from the double-stacked rail cars below. Trucks idle in neatly organized lanes, their drivers waiting for the signal to pull forward. In the distance, a freight train rumbles slowly toward the yard, its cars loaded with cargo from hundreds of miles away.

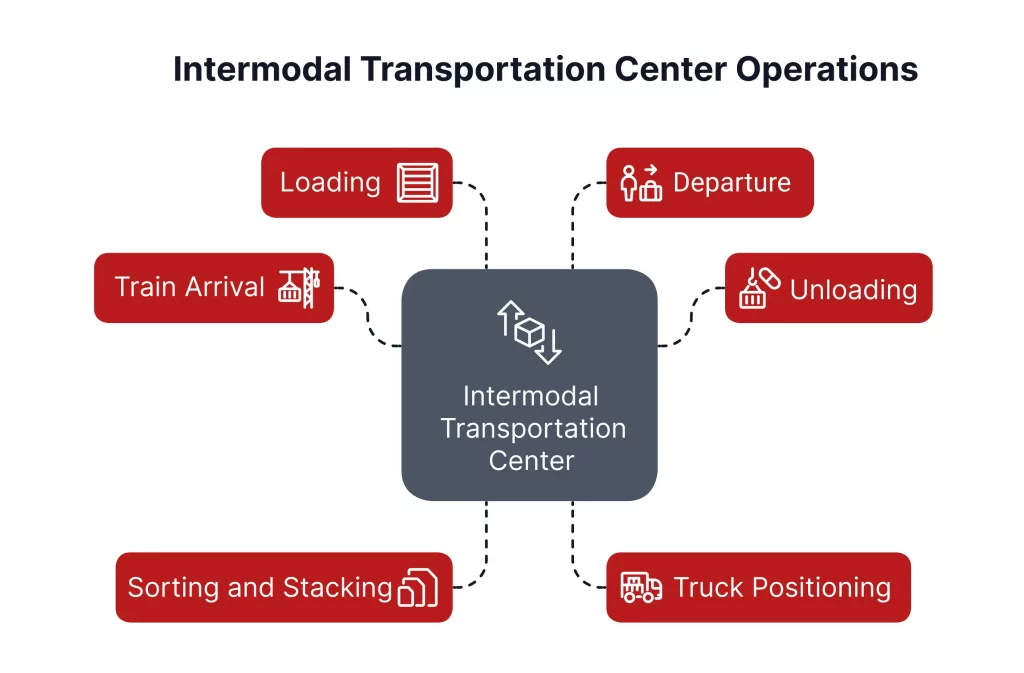

An intermodal transportation center is not just a place. It is a carefully choreographed stage where rail, truck, and sometimes ship come together in a continuous exchange. Here, the goal is simple: move freight from one mode of transport to another as quickly and efficiently as possible.

Every container tells a story. Some have just arrived from a port, ready to be loaded onto trucks for regional delivery. Others are headed the opposite way, picked up from manufacturers or distribution centers and bound for rail shipment across the country. Inside the center, thousands of these movements happen each day, timed down to the minute so nothing falls behind schedule.

Walk a little further in, and you will see the heartbeat of the operation — dispatch offices with large digital boards tracking every inbound and outbound load. These screens are where the flow is monitored, delays are spotted, and solutions are implemented before problems turn into costly downtime.

For trucking companies, this is where having a partner like REACH can make a difference. If a vehicle in this chain breaks down on the way to or from the center, the clock is ticking. REACH’s nationwide network of vetted service providers can respond in real time, keeping that cargo on track for its next connection.

Inside an intermodal center, every minute matters. Every mile matters. And every piece of equipment — from the largest crane to the smallest yard truck — plays a part in keeping freight flowing without interruption.

Key Takeaways

An intermodal transportation center is a precision-driven freight hub

It brings together rail, trucks, and sometimes ships to transfer containers quickly, efficiently, and with minimal disruption.

Every step is tightly choreographed to reduce delays

From check-in at the gate to outbound scheduling, each movement is part of a larger system designed to keep freight moving on time.

Technology powers the entire operation behind the scenes

Tools such as GPS tracking, automated cranes, dispatch software, and surveillance systems provide real-time visibility, ensuring safety and efficiency.

Coordination is what holds it all together.

Yard managers, dispatchers, crane operators, and drivers must stay in sync to prevent bottlenecks and ensure efficient operations. Constant communication is essential to maintain the rhythm.

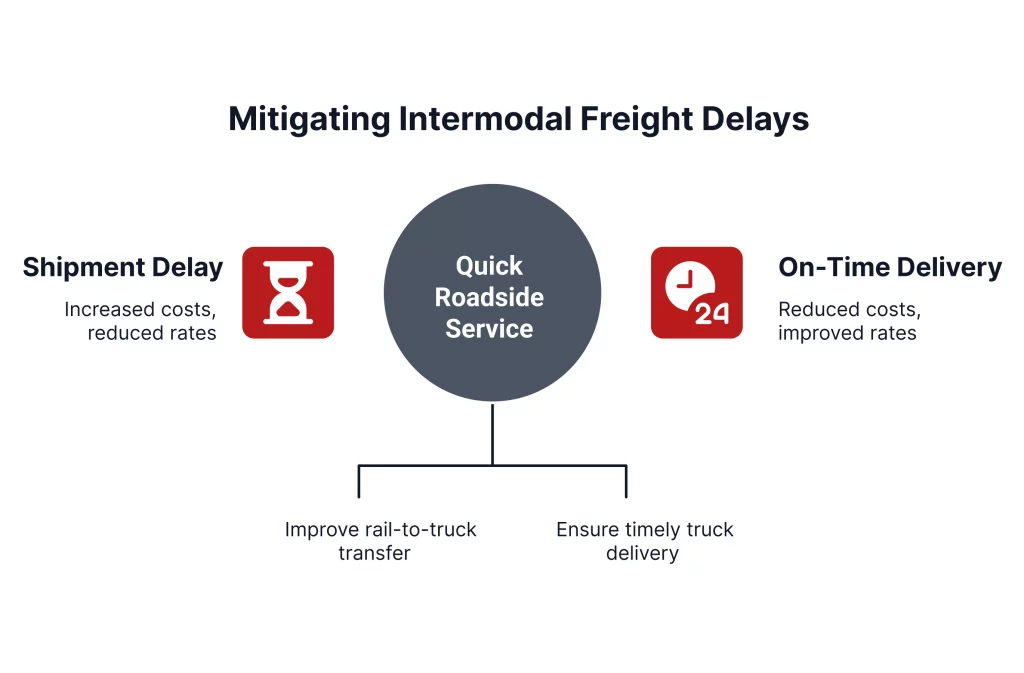

Breakdowns and delays are critical risks.

In a time-sensitive setup, even a flat tire can cause a ripple effect. That’s why quick-response services like REACH are vital to keeping freight on schedule.

Speed is directly tied to cost and reputation.

Late shipments can result in penalties, lost revenue, and strained customer relationships. Consistently on-time delivery builds long-term business success.

REACH strengthens your response capabilities

Its nationwide network connects fleets to trusted repair services in minutes, turning potential delays into smooth recoveries.

A competitive edge starts with reliability.

Intermodal freight companies that respond faster, recover smarter, and communicate clearly gain customer trust and industry credibility.

The Heart of Freight Flow – Step-by-Step Journey

Freight does not move through an intermodal transportation center by chance. Every shift follows a rhythm that keeps thousands of tons of cargo moving smoothly. Here’s how it works from the moment a shipment arrives to the second it leaves for its next destination.

1. Arrival at the Gate

Every journey starts with a check-in. Trucks pull up to entry gates where automated systems scan container IDs and match them to scheduled arrivals. Trains arriving from long-haul routes are guided onto dedicated tracks inside the yard. Timing is critical — a few minutes’ delay here can ripple through the rest of the schedule.

2. Unloading and Staging

Once inside, the real work begins. Massive gantry cranes and stackers lift containers from train cars or truck trailers. Each container is placed in a designated staging area and sorted according to its next destination. This is where yard organization makes or breaks efficiency.

3. Inspection and Documentation

Before any cargo moves on, it is checked. For some loads, that means a quick visual inspection. For others, especially those crossing borders, it involves scanning, customs paperwork, and safety checks. Digital tracking systems log every movement to keep the chain of custody intact.

4. Mode Transfer

This is the defining moment of intermodal freight. Containers are shifted from one mode of transport to another, usually rail to truck, truck to rail, or sometimes to a waiting ship. Specialized equipment ensures transfers happen quickly and without damage.

5. Outbound Scheduling

Once containers are loaded onto their new transport, dispatch teams assign them to specific departure slots. Trucks may head straight onto highways for last-mile delivery. Trains roll out on tight timetables to connect with other freight hubs.

For trucking companies and logistics providers, any breakdown or equipment issue in this chain can cause costly delays. This is why having immediate support matters. If a truck carrying a time-sensitive load to or from the center breaks down, REACH can connect it with the nearest qualified service provider in minutes, keeping that cargo on schedule.

A Day Inside an Intermodal Transportation Center

Technology Behind the Movement

What makes an intermodal transportation center work so smoothly is not just the heavy equipment you can see. Behind every lift, transfer, and departure is a network of technology that keeps everything in sync.

Container Tracking Systems

Every container in the yard has a unique ID that can be tracked in real time. This helps operators know exactly where each load is, when it arrived, and when it needs to move. For shippers and carriers, this visibility reduces the risk of lost cargo and makes scheduling more predictable.

GPS and Telematics

Trucks serving the center are often equipped with GPS units and telematics devices. These tools send live location updates to dispatch teams, allowing them to adjust schedules if a truck is running late. For fleets connected with a service network like REACH, these same tools can be used to share breakdown locations instantly with nearby repair providers.

Automated Cranes and Sorting Systems

Large gantry cranes, automated stacking cranes, and advanced reach stackers can move containers with precision and speed. In many centers, these machines are guided by software that tells them exactly which container to move and where to place it next.

Scheduling and Coordination Software

Inside the control room, large digital boards and computer systems manage every incoming and outgoing load. These platforms balance the workload, prevent bottlenecks, and ensure each mode transfer happens on time.

Safety and Security Technology

Sensors, surveillance cameras, and access control systems help keep the yard secure. Safety alerts are sent to operators if machinery malfunctions or if any unsafe conditions are detected.

This mix of physical equipment and digital intelligence enables thousands of containers to be processed each day without chaos. When all systems work together, freight moves faster, downtime is reduced, and the entire operation becomes more reliable.

The Role of Coordination

Even with the best technology, an intermodal transportation center runs on people. Coordination is what turns a yard full of containers, trucks, and trains into a smooth, continuous flow of freight.

Yard Managers and Dispatchers

Yard managers oversee container placement, equipment movement, and traffic flow inside the center. Dispatchers manage incoming and outgoing trucks, making sure each load is picked up and delivered on time. They work closely with rail operators, crane crews, and truck drivers to keep everything on schedule.

Communication is Key

A delay in one part of the operation can quickly affect everything else. That is why constant communication between the control room, yard teams, and drivers is essential. Whether it is adjusting to a delayed train or rerouting a truck around traffic, these updates keep the chain moving.

Handling Disruptions

Breakdowns, equipment malfunctions, and weather delays can happen at any time. The difference between a minor setback and a costly delay often comes down to how quickly help arrives. This is where a service partner like REACH becomes valuable. If a truck carrying a load for the next train departure has a flat tire or mechanical issue, REACH can instantly connect the driver to the closest qualified service provider. By reducing downtime, the cargo stays on track for its scheduled transfer.

Teamwork Across Modes

A well-coordinated team, supported by fast-response service networks, is the backbone of any high-performing intermodal transportation center. Without it, the entire flow would slow, costs would rise, and reliability would suffer.

Why Speed Matters in Intermodal Freight

In intermodal freight, time is more than money. It is the difference between meeting a customer’s delivery window and paying penalties for delays. Every step in the journey, from unloading a train to loading a truck, is tied to a schedule that has almost no room for error.

Tight Connections Between Modes

A train arriving even thirty minutes late can cause trucks to miss their scheduled departures. This creates a chain reaction where deliveries get pushed back, warehouses adjust receiving schedules, and costs begin to rise.

Cost of Delays

Delays can trigger late fees from customers, additional storage charges at yards, and extra fuel costs if trucks have to make up lost time. For perishable goods, delays can mean spoiled shipments and complete losses.

The Role of Quick Response

Equipment breakdowns and driver issues are common risks in trucking. In an intermodal environment, these issues can quickly escalate because they affect a time-sensitive transfer. That is why rapid response is essential. With a network like REACH, fleets have direct access to service providers who can respond quickly, whether the problem is a flat tire, a mechanical fault, or a minor repair. Every minute saved in the repair process is a step toward keeping the freight flow on schedule.

Competitive Advantage

Shippers and carriers who can consistently meet deadlines build stronger relationships with customers. In an industry where reputation matters, being known for reliability can win more business and secure long-term contracts.

The Cost of Delay in Intermodal Freight

Turning Freight Flow Into a Competitive Edge

An intermodal transportation center is a place where precision meets speed. Every container, every truck, every crane move plays a role in keeping the supply chain running on time. But even the best-run operations face challenges — equipment breakdowns, unexpected delays, and last-minute changes in scheduling.

That is where having the right support network changes everything. REACH is built for the kind of time-sensitive environment that defines intermodal freight. By connecting fleets directly to a nationwide network of qualified service providers, REACH ensures that help is never far away.

Whether your truck is minutes from its train connection or already inside the yard, you can get the service you need quickly, so your cargo stays on schedule.

The result is not just fewer delays. It is stronger customer relationships, lower operational costs, and a reputation for reliability that keep businesses coming back. In a world where every minute counts, REACH gives you the ability to respond fast, stay on track, and keep freight moving.

If your goal is to make intermodal freight a strength rather than a stress point, partnering with REACH is the next step.

Frequently Asked Questions (FAQs)

-

What is an intermodal transportation center?

An intermodal transportation center is a hub where freight is transferred between different modes of transport, such as rail and truck, to move goods efficiently across long distances.

-

How does freight move through an intermodal transportation center?

Freight typically arrives by train, is unloaded by cranes, sorted in the yard, loaded onto trucks, and then delivered to its next destination. Each step is carefully timed and coordinated.

-

Why is speed so important in intermodal freight?

Speed ensures that cargo meets delivery schedules, avoids costly delays, and keeps the supply chain running smoothly. Even short delays can cause a chain reaction of missed connections and increased costs.

-

What technology is used in an intermodal transportation center?

These centers use GPS tracking, container management software, automated cranes, scheduling systems, and security monitoring to manage thousands of containers daily.