When a vehicle is taken off the road for repairs, every hour counts; downtime means missed deliveries, frustrated customers, and lost revenue. For many fleets, the real cause of extended downtime is not the repair itself but the way the repair process is managed. Paper forms get misplaced, emails are overlooked, and managers often lack visibility into which vehicles are waiting for service or how long repairs will take.

Work order tracking systems solve this challenge by digitizing the repair process. Every defect logged becomes a service request, every repair is tracked in real time, and managers always know when vehicles will return to service. This article explains what work order tracking systems are, how they streamline repairs, and why REACH makes them more effective for modern fleets.

Key Takeaways

- Manual work order management causes delays, compliance risks, and hidden costs.

- A digital work order tracking system centralizes requests, automatically creates service tickets, and ensures accountability.

- Benefits include reduced downtime, stronger compliance, cost savings, and better communication across teams.

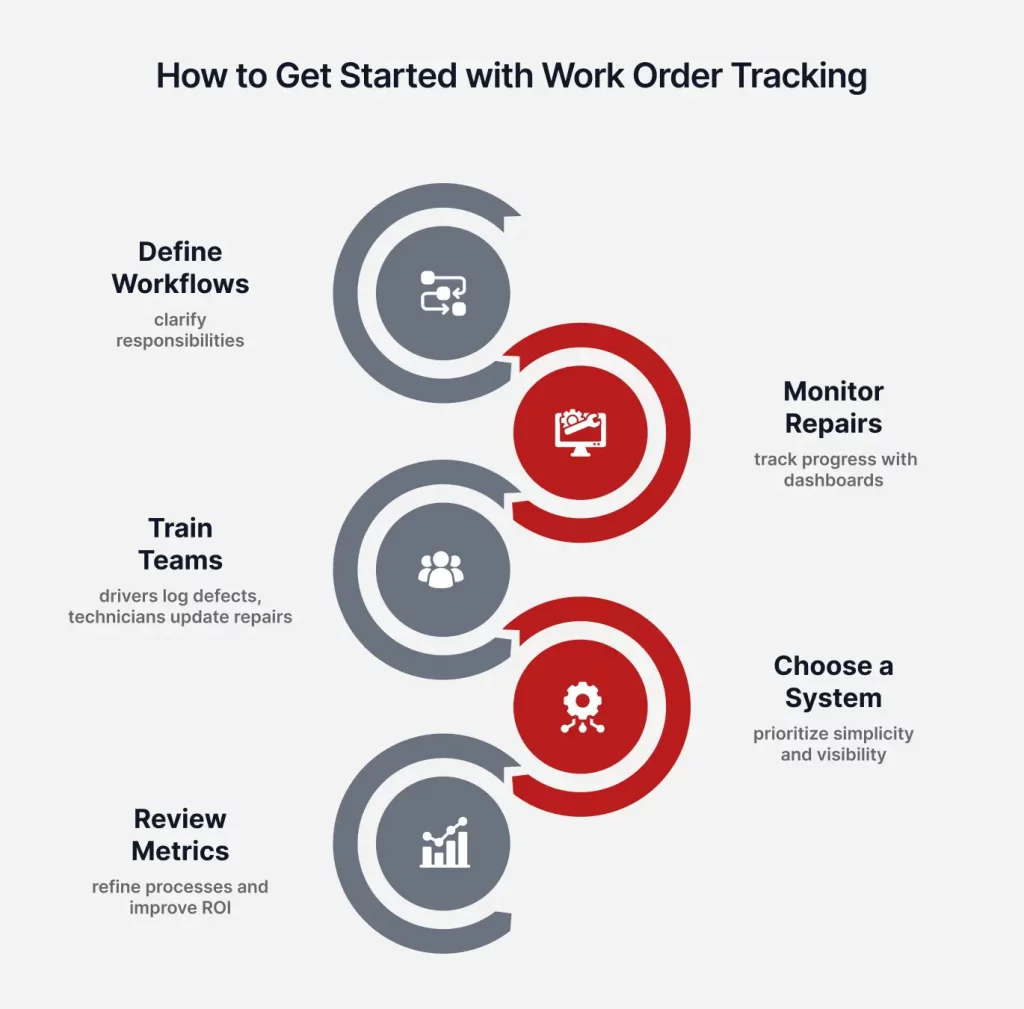

- Implementation requires defining workflows, training teams, monitoring repairs, and reviewing metrics for improvement.

- REACH simplifies work order tracking by digitizing inspections, automating service creation, and ensuring compliance audit readiness.

- Fleets using REACH gain reliability, customer trust, and a faster return on investment.

The Problem with Manual Work Orders

For years, many fleets have relied on paper forms, spreadsheets, and scattered emails to manage repairs. While these methods may have been acceptable in the past, they create serious inefficiencies in today’s fast-moving logistics environment.

Lost or Delayed Requests

Paper-based systems are often unreliable. A defect noted during a driver’s walkaround might never reach the service team in time. Even when it does, delays in communication unnecessarily extend downtime.

Lack of Visibility

With manual processes, managers rarely have a clear view of pending repairs, vehicles in service, or estimated completion times. This lack of visibility causes poor scheduling, missed deliveries, and frustration across teams.

Compliance Gaps

Work orders also act as compliance records. When paper logs are incomplete or inaccurate, fleets risk fines during audits. Missing repair documentation can also create liability issues if vehicles are involved in incidents.

Inefficient Workflows

Without automation, service managers spend hours coordinating repairs, assigning technicians, and ensuring parts are available. This slows down the repair cycle and increases costs.

Manual work order management increases downtime, creates compliance risks, and adds unnecessary expenses. Fleets that want to remain competitive in 2026 need a smarter way to handle repairs.

What is a Work Order Tracking System

A work order tracking system is a digital platform that manages every step of the repair process for fleet vehicles. Instead of relying on paper forms or scattered emails, fleets utilize a centralized system to log defects, create repair requests, assign technicians, track progress, and close work orders, maintaining complete records.

Definition and Purpose

At its core, a work order tracking system provides structure and visibility. Drivers log issues during inspections, managers create service requests instantly, and technicians update the status as repairs move forward. The system ensures that no repair slips through the cracks and minimizes downtime.

Core Elements of a Work Order Tracking System

Defect Logging

Drivers or inspectors identify issues during walkarounds or inspections. These defects are entered into the system immediately.

Service Request Creation

Once a defect is logged, the system generates a service request that includes details such as the vehicle, the issue, and the level of urgency.

Technician Assignment

Service managers assign the request to a technician, ensuring accountability and faster response times.

Repair Tracking

Progress is tracked in real time. Managers see what is pending, in progress, or completed, reducing guesswork.

Work Order Closure

Once the repair is completed, the work order is closed, and a digital record is saved for compliance and future reference.

Why It Matters

A work order tracking system is more than just a repair log. It is a workflow engine that ensures every defect reported is addressed promptly, every repair is tracked accurately, and every record is readily available when needed. For fleets, this translates into less downtime, stronger compliance, and smoother operations.

How Work Order Tracking Streamlines Repairs

A strong work order tracking system does more than organize repair requests. It speeds up every step of the process, reduces miscommunication, and keeps managers in control of fleet uptime. By digitizing and centralizing repair workflows, fleets eliminate the bottlenecks that often prolong downtime.

Centralized Requests

With all defects and repair needs logged in one system, nothing gets lost. Drivers submit issues directly through digital forms, and managers see them immediately. This eliminates the risk of misplaced paperwork and ensures that service requests are addressed promptly.

Automatic Service Creation

Instead of waiting for manual follow-ups, work order tracking systems automatically generate service requests from inspection reports, streamlining the process. If a driver records a defect, the system creates a work order instantly. This automation streamlines processes, reducing delays and ensuring that every issue is thoroughly documented.

Real-Time Visibility for Managers

Managers can view the status of all repairs in progress. They know which vehicles are waiting, which are in service, and when they are expected to return to the road. This visibility allows for better scheduling and fewer disruptions to delivery commitments.

Clear Timelines for Technicians

Technicians receive assigned work orders that include all relevant details. They can update the status as they work, which keeps managers informed without the need for repeated phone calls or check-ins. Repairs move forward faster and with less friction.

Scenario in Practice

Consider a fleet where a driver logs a brake issue during a morning inspection. In a manual system, the note might be overlooked until the vehicle fails on the road. With a work order tracking system, the defect creates a service request immediately, the technician is assigned, and the repair is completed before the vehicle leaves the lot. Downtime is avoided entirely, and the vehicle remains road-ready.

How Work Order Tracking Works in a Fleet

Benefits of Work Order Tracking Systems

Adopting a work order tracking system is not just about going paperless; it’s about streamlining processes and enhancing efficiency. It is about building a faster, smarter, and more reliable repair process that protects uptime and strengthens accountability. Fleets that implement these systems gain measurable benefits across operations.

Reduced Downtime

The most immediate benefit is less downtime. When defects are logged instantly and service requests are created automatically, repairs begin sooner. Vehicles spend less time waiting for maintenance and more time on the road, generating revenue.

Compliance Confidence

Every work order creates a timestamped, digital record tied to the vehicle. During audits or roadside inspections, fleets can show proof of inspection, repair, and closure with a few clicks. This reduces compliance risk and ensures vehicles remain road-ready.

Stronger Accountability

A digital system assigns every repair to a technician and tracks progress in real time. Drivers know their reports are being acted upon, technicians are accountable for completion, and managers have full visibility into every step. This eliminates blame shifting and builds a culture of responsibility.

Cost Control Through Efficiency

Downtime is expensive, and so are unplanned repairs. Work order tracking systems reduce both by catching issues early and streamlining repair cycles. Fleets spend less on emergency breakdowns and avoid revenue loss from idle vehicles. Over time, these savings make the system pay for itself.

Better Communication Across Teams

When everyone works from the same system, communication improves. Drivers report issues digitally, service managers assign and track repairs, and technicians update the status in real-time. This eliminates back-and-forth emails and phone calls while keeping everyone aligned.

Customer Trust and Reliability

Fleets that reduce downtime also improve reliability. On-time deliveries and fewer disruptions build customer trust. Over time, this operational strength becomes a competitive advantage that helps fleets secure and retain contracts.

Implementing a Work Order Tracking System

A work order tracking system delivers the most value when it is set up with clear workflows and consistently used. Implementation does not have to be complex. By following a step-by-step approach, fleets can transition smoothly and effectively from manual methods to digital tracking.

Step 1: Define Repair Workflows

Start by mapping how repairs currently move through the fleet. Identify who logs defects, who approves repairs, who assigns technicians, and who closes work orders. Clarifying this process ensures the system aligns with real-world operations, rather than creating new bottlenecks.

Step 2: Choose the Right System

Not all systems are created equal. Fleets should seek user-friendly solutions that integrate seamlessly with existing hardware and offer real-time visibility. The system should simplify workflows rather than overwhelm managers with unnecessary features.

Step 3: Train Drivers and Technicians

Drivers need to know how to log defects accurately, and technicians must understand how to update work orders in real-time. Short, practical training sessions help ensure adoption and implementation. Emphasizing how the system reduces downtime makes it easier to secure buy-in.

Step 4: Monitor Repairs in Real Time

Once the system is in place, managers should use dashboards to track repairs from start to finish. Monitoring ensures accountability, prevents delays, and provides insight into repair timelines for better scheduling.

Step 5: Review Metrics and Improve

Implementation is not a one-time project. Managers should review data on downtime, repair costs, and defect trends to refine processes. Continuous improvement ensures the system delivers maximum ROI over time.

Steps to Implement Work Order Tracking in Fleets

Why REACH Makes Work Order Tracking Simple

Many fleets recognize the need to modernize their repair workflows, but the fear of complex systems often holds them back. REACH removes this barrier by making work order tracking intuitive, connected, and compliance-ready. It provides managers, drivers, and technicians with a single system that converts repair requests into uptime gains.

From Inspections to Service Requests

In REACH, the process begins the moment a defect is logged. Instead of waiting for paperwork or manual data entry, the system automatically creates a service request. Nothing is overlooked, and repairs begin faster.

Real-Time Repair Tracking

REACH provides complete visibility into the status of every repair. Managers can see which requests are pending, which are in progress, and which vehicles are ready for dispatch. This transparency enables fleets to plan routes, allocate resources, and minimize downtime.

Compliance Built In

Every inspection, repair, and completed work order is tied to the vehicle’s profile with a timestamped digital record. During audits or roadside checks, fleets can present accurate documentation instantly. Compliance becomes an integral part of the daily workflow, rather than a separate burden.

Simple Dashboards for Every User

REACH is designed to be practical. Drivers have straightforward tools to log issues, technicians have clear repair assignments, and managers have dashboards that provide a comprehensive view of the entire picture. This simplicity ensures adoption and keeps the focus on outcomes.

ROI That Shows Quickly

By reducing downtime, eliminating compliance risks, and cutting manual coordination costs, REACH helps fleets see measurable ROI in a short time. Repairs are streamlined, vehicles return to service faster, and customer reliability improves.

Why It Matters

Repair delays can cost fleets more than the actual repair itself. With REACH, work order tracking becomes seamless, consistent, and efficient. Fleets protect uptime, reduce costs, and gain the confidence that every repair is handled properly.

Turning Repairs into a Strength

Repairs are inevitable in fleet operations, but long downtime does not have to be. The difference between lost revenue and reliable uptime often lies in how repairs are managed. Manual processes create delays, poor visibility, and compliance risks, while digital work order tracking systems bring structure, speed, and accountability.

By centralizing repair requests, automating service creation, and providing real-time visibility, work order tracking systems turn maintenance into a strategic advantage. Fleets that embrace this approach reduce downtime, control costs, and deliver better service to their customers.

REACH makes this process simple and effective. With inspections that trigger service requests automatically, dashboards that track repairs in real-time, and compliance-first workflows, REACH ensures that no defect goes unaddressed. The result is a system that keeps vehicles road-ready, reduces stress for managers, and delivers measurable ROI.

Work order tracking is more than a tool. It is the key to transforming repairs from a drain on resources into a driver of operational strength.

Frequently Asked Questions (FAQs)

-

What is a work order tracking system for fleets?

A work order tracking system is a digital tool that manages repair requests, assigns technicians, tracks progress, and closes repairs with complete records. It ensures every defect logged is addressed quickly and efficiently.

-

How does work order tracking reduce downtime?

By automatically creating service requests, providing real-time visibility, and keeping managers informed, work order tracking shortens repair cycles. It gets vehicles back on the road more quickly.

-

What features should a work order tracking system include?

Core features include defect logging, automated service creation, technician assignment, real-time repair tracking, and digital closure with compliance-ready records.

-

How is digital work order tracking better than paper-based systems?

Paper forms and emails often get lost or delayed, leading to longer downtime. Digital tracking centralizes all requests, ensures accountability, and maintains compliance documentation in a secure and accessible manner.

-

Does a work order tracking system help with compliance?

Yes. Each inspection, repair, and completed work order is tied to the vehicle’s profile with timestamped digital records, making fleets audit-ready at all times.

-

Why choose REACH for work order tracking?

REACH simplifies repair management by automatically converting inspections into service requests, tracking progress in real-time, and delivering compliance-first workflows that reduce downtime and increase ROI.