Global supply chains may span continents, but no shipment reaches its destination without the aid of trucks. Even when cargo travels by sea or rail for most of the journey, it is trucks that handle the first mile from factories or warehouses and the last mile to distribution centers or customer locations. This critical role is called intermodal trucking.

Intermodal trucking connects the dots in intermodal logistics by moving standardized containers between terminals, ports, and customer sites. Without reliable trucking operations, the efficiency of rail and ocean shipping cannot be realized. As demand for faster, greener, and more cost-effective shipping increases, understanding intermodal trucking has become essential for both shippers and fleet operators.

This guide explains what intermodal trucking is, how it works, its benefits and challenges, and how technology and compliance tools, such as REACH, help fleets succeed in this rapidly changing environment.

Key Takeaways

- Intermodal trucking involves moving containers between various modes, including ports, rail yards, warehouses, and customer sites.

- It differs from long-haul OTR trucking by focusing on shorter, frequent trips.

- Benefits include lower costs, reduced driver fatigue, greener operations, and access to wider markets.

- Challenges include port congestion, chassis shortages, scheduling complexity, and compliance with regulatory requirements.

- Safety and compliance depend on DVIRs, HOS tracking, and preventative maintenance.

- Technology provides GPS visibility, automated service management, and digital compliance.

- REACH strengthens intermodal trucking by ensuring fleets remain compliant, visible, and road-ready.

What Is Intermodal Trucking

Intermodal trucking refers to the use of trucks to transport shipping containers as part of a larger intermodal logistics network. Instead of carrying freight directly from origin to destination over long distances, intermodal trucks move containers between modes such as ships, trains, and warehouses.

Containers as the Core

The system relies on standardized containers, typically 20-foot or 40-foot boxes, that can be transferred across trucks, trains, and ships without requiring the cargo to be unloaded. This makes intermodal trucking efficient because trucks pick up and drop off sealed containers rather than repacking goods.

Intermodal Trucking vs Over-the-Road (OTR) Trucking

It is important to distinguish intermodal trucking from traditional over-the-road trucking:

- Intermodal trucking focuses on shorter hauls, usually between ports, terminals, and local warehouses. Trips are frequent but shorter in distance.

- OTR trucking covers long-haul routes, where drivers transport goods directly across states or regions without transferring containers to another mode.

Why It Matters

Intermodal trucking is a vital connector. It ensures containers transition smoothly between large-scale transport modes, such as ships and trains, and the local delivery networks that reach businesses and consumers. Without dependable trucking, intermodal logistics cannot function effectively.

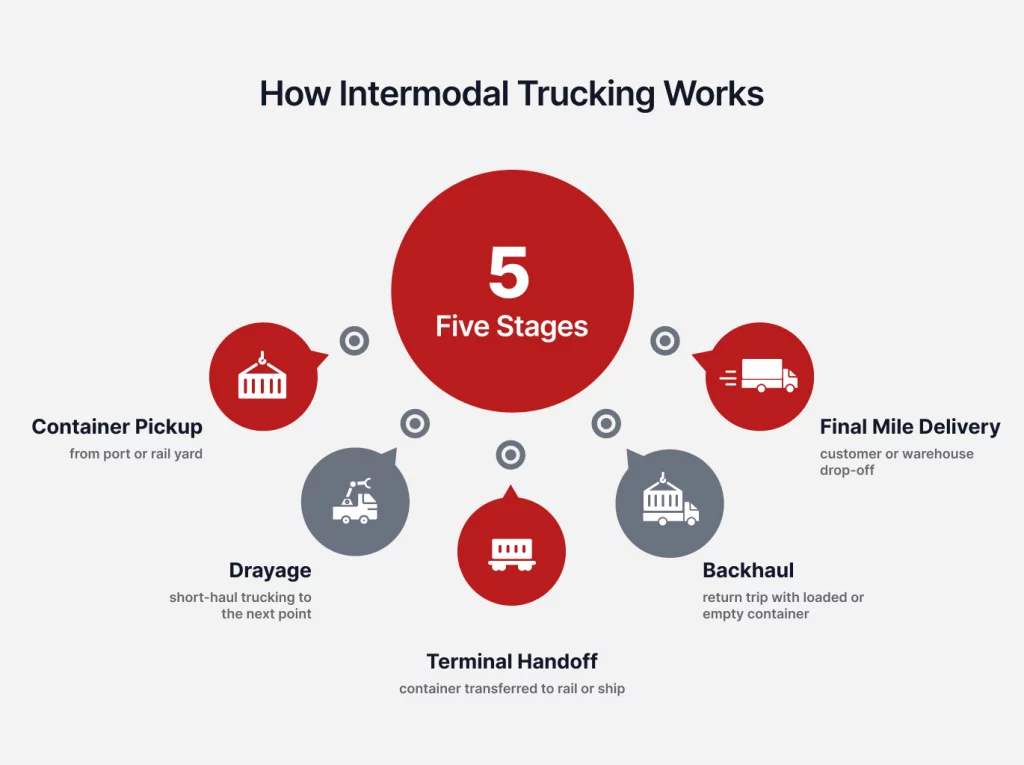

How Intermodal Trucking Works

Intermodal trucking is built around precision and timing. Every move matters because trucks operate at the intersection of multiple carriers, terminals, and schedules. Here is how the process typically unfolds.

Step 1: Container Pickup

The journey starts when a truck picks up a loaded container from a ship at a port or from a rail terminal. In some cases, trucks also collect empty containers from a depot to deliver them back to shipping lines for reuse.

Step 2: Drayage to the Next Mode

The truck hauls the container a short distance, a movement commonly referred to as drayage. This may involve transporting the container from a port to an inland rail yard, or from a rail yard to a warehouse or distribution center. Drayage trips are usually measured in hours rather than days.

Step 3: Terminal Handoff

At the next terminal, the container is transferred to another mode, such as being lifted from the truck chassis onto a railcar or stacked onto a ship. These handoffs are highly coordinated and depend on both equipment availability and terminal capacity.

Step 4: Return or Backhaul

After completing the drop-off, trucks often return with another container, either loaded or empty. Backhaul efficiency reduces deadhead miles, helping fleets optimize their revenue.

Step 5: Final Mile Delivery

In some cases, intermodal trucking handles the last mile as well, delivering the container directly to a customer location. This stage is often the most visible to customers and requires strict timing to meet delivery windows.

The Intermodal Trucking Process

Benefits of Intermodal Trucking

Intermodal trucking plays a specialized role in the supply chain, and its advantages extend far beyond simply moving containers from point A to point B. When executed well, intermodal trucking supports cost efficiency, sustainability, and market reach in ways that benefit both shippers and carriers.

Lower Transportation Costs

By handling shorter hauls and connecting cargo to rail and sea routes, intermodal trucking reduces reliance on expensive long-haul trucking. Rail is often two to three times more fuel-efficient than road, which means businesses can lower costs by letting trucks manage only the first and last miles of their routes.

Reduced Driver Fatigue

Because intermodal trips are shorter, drivers spend fewer hours behind the wheel compared to traditional over-the-road hauls. This reduces fatigue, improves safety, and helps carriers retain drivers who prefer to be home more frequently.

Environmental Benefits

Intermodal trucking contributes to sustainability by minimizing unnecessary long-haul trucking miles. When combined with rail or sea transport, the carbon footprint per shipment decreases significantly. Many companies highlight intermodal shipping as part of their green logistics initiatives.

Access to Wider Markets

Trucks provide the flexibility to connect inland regions to global ports and rail hubs. A business located far from a seaport can still participate in international trade because intermodal trucking links it to larger networks.

Improved Reliability

When paired with rail or sea transport, intermodal trucking reduces risks associated with highway congestion or driver shortages. Containers are moved on consistent schedules across modes, while trucks ensure cargo still reaches its final destination on time.

Scalability for Shippers

As demand increases, intermodal trucking allows businesses to scale without dramatically expanding their private fleets. The standardized nature of container handling facilitates the efficient management of higher shipment volumes.

Challenges in Intermodal Trucking

Intermodal trucking is crucial for connecting ports, rail yards, and distribution centers. Still, it also presents its own set of challenges. These challenges often impact delivery timelines, operating costs, and overall efficiency.

Port and Terminal Congestion

Busy ports and rail yards frequently struggle with congestion, resulting in lengthy wait times for trucks. Delays not only reduce driver productivity but also increase costs for shippers who may face detention and demurrage fees.

Limited Chassis Availability

Containers require specialized chassis for transport. During peak demand, shortages of available chassis can cause operations to stall and create bottlenecks. Without enough chassis, even available trucks cannot move containers on time.

Complex Scheduling

Intermodal trucking depends on tight coordination with ship schedules, train timetables, and terminal operations. If one link in the chain falls behind, it disrupts the entire process. Managing multiple carriers and schedules can be a resource-intensive task.

Regulatory Compliance

Drivers and fleets must adhere to a range of regulations, including Hours of Service (HOS) limits, safety standards, and environmental requirements. Ensuring compliance while operating on tight schedules can be challenging, especially when regulations vary by region.

Equipment and Maintenance Demands

Since intermodal trucks often operate in stop-and-go environments, such as ports and yards, they experience higher wear and tear. Without strong maintenance programs, fleets risk breakdowns that further delay shipments.

Visibility Gaps

Because cargo is switched between different carriers and modes, visibility can be lost when containers are moved off the truck. Without integrated tracking systems, shippers and customers may be left guessing about shipment status.

Compliance and Safety in Intermodal Trucking

Compliance is not optional in the intermodal trucking industry. Because trucks often operate in high-traffic zones, such as ports, rail yards, and city centers, safety and regulatory standards are closely scrutinized. Fleets that manage compliance well protect drivers, reduce downtime, and build stronger relationships with shippers.

Driver Vehicle Inspection Reports (DVIRs)

Federal regulations require drivers to complete DVIRs to confirm that trucks are safe for operation. For intermodal fleets, DVIRs are especially important, as vehicles frequently make short trips and experience high wear in terminal environments. Digital DVIRs streamline the process, making records audit-ready while reducing paperwork.

Hours of Service (HOS) Compliance

Intermodal trucking usually involves shorter hauls, but drivers still must comply with HOS rules. Accurate logging ensures drivers avoid fatigue and remain within legal limits. Electronic logging devices (ELDs) make it easier to track HOS automatically, minimizing compliance risks.

Terminal and Port Safety Requirements

Ports and rail yards often enforce additional safety measures, from ID verification to PPE rules. Fleets must train drivers to follow these standards to prevent delays and safety violations.

Inspection Records and Audit Readiness

Regulators and shippers alike may request inspection and compliance records at any time. Maintaining clear, digital records ensures fleets can provide proof of compliance quickly. This not only avoids penalties but also strengthens a fleet’s credibility with logistics partners.

The Role of Preventative Maintenance

Compliance goes hand in hand with vehicle maintenance. Regular inspections and preventative service reduce breakdowns in high-pressure environments. This ensures that trucks stay road-ready and avoid costly delays when schedules are already tight.

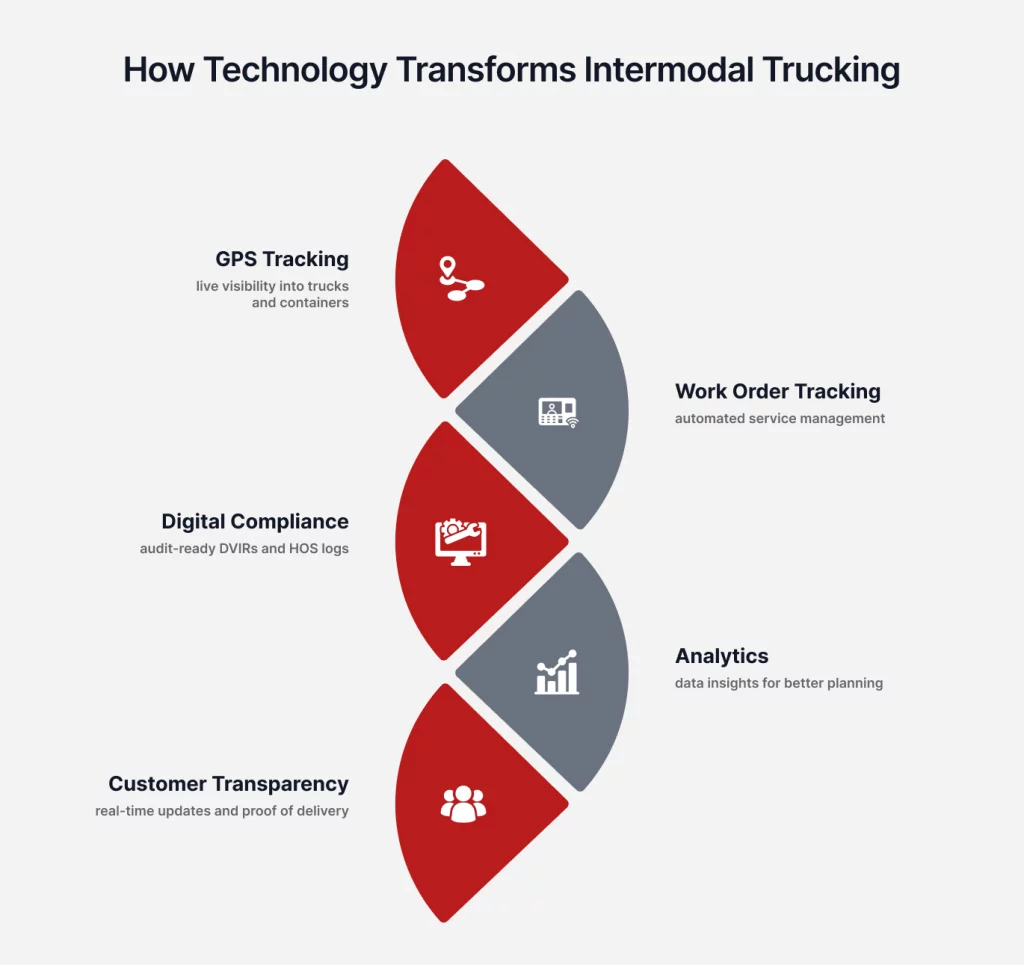

Technology’s Role in Intermodal Trucking

Technology is transforming intermodal trucking by closing visibility gaps, automating compliance, and improving fleet efficiency. With multiple carriers, terminals, and schedules involved, digital tools give fleets the control they need to keep containers moving smoothly.

GPS Tracking and Real-Time Visibility

GPS tracking ensures that managers are always aware of the location of trucks and containers. Real-time updates reduce the risk of missed deadlines, enhance coordination with terminals, and provide shippers with confidence that their cargo is on schedule.

Automated Work Order Tracking

Frequent short hauls and stop-and-go movements at ports create heavy strain on trucks. Automated work order tracking helps fleets schedule and manage maintenance efficiently. Service requests are triggered digitally from inspections, reducing downtime and ensuring vehicles remain road-ready.

Digital Compliance Logs

Electronic systems capture Hours of Service data, DVIRs, and inspection records in a single location. This eliminates paper-based errors and makes fleets audit-ready at any moment. Automated compliance tracking enables drivers to stay focused on operations while minimizing the risk of penalties.

Data-Driven Planning

Analytics within fleet platforms reveal performance trends, such as average wait times at terminals or common maintenance issues. Fleets can utilize these insights to optimize routes, schedule preventive maintenance, and negotiate more favorable contracts with shippers and carriers.

Customer Transparency

Technology allows fleets to provide customers with shipment updates, ETAs, and proof of delivery. This transparency fosters trust and enables shippers to differentiate themselves in competitive markets.

Technology Tools for Intermodal Trucking

Why REACH Strengthens Intermodal Trucking

Intermodal trucking is only as strong as the fleets that power it. Every delay, compliance gap, or breakdown can ripple across ports, rail yards, and customer delivery schedules, potentially impacting multiple areas. This is where REACH provides an advantage. By combining compliance-first workflows, real-time visibility, and automated service management, REACH empowers fleets to handle intermodal demands with confidence.

Keeping Vehicles Road-Ready

Frequent trips in stop-and-go port environments increase wear and tear on vehicles. REACH digitizes inspections and ties them directly to service requests, ensuring that preventative maintenance is never skipped. Trucks stay road-ready, and downtime is minimized.

Compliance Without the Paperwork

From DVIRs to Hours of Service logs, compliance requirements in intermodal trucking are strict. REACH makes these records digital, accurate, and audit-ready. Fleets avoid fines and delays while proving reliability to logistics partners.

Real-Time Tracking That Matches Intermodal Pace

REACH provides live visibility into truck and container locations. Managers can view shipments in real-time, even when schedules at ports or rail yards change. This transparency enables fleets to adjust quickly and maintain optimal service levels.

Faster Response Through Automation

When inspections flag issues, REACH automatically generates work orders. Dispatchers and mechanics are notified instantly, so repairs happen before trucks are needed for the next pickup. This automation ensures that intermodal schedules stay on track.

Customer Confidence Through Transparency

Shippers want to know their containers are moving as promised. REACH allows fleets to share accurate ETAs and proof of compliance, reinforcing trust and securing repeat business.

A Stronger Link in the Intermodal Chain

Trucking connects global logistics to local delivery. By improving visibility, compliance, and uptime, REACH ensures fleets become the dependable link that keeps intermodal supply chains flowing.

The Power of Intermodal Trucking

Intermodal trucking is the vital link that connects global shipping to local delivery. By moving containers between ships, trains, warehouses, and customers, trucks ensure that supply chains remain efficient and reliable. While challenges such as congestion, compliance, and equipment shortages are real, technological and process improvements are making intermodal trucking more resilient than ever.

For fleets, success hinges on visibility, compliance, and uptime. Trucks must be road-ready, drivers must adhere to regulations, and managers need real-time data to make informed decisions. REACH delivers these capabilities in one platform, transforming intermodal trucking from a high-risk operation into a dependable part of global logistics.

As demand for faster and greener transportation continues to grow, intermodal trucking will play an increasingly significant role. Fleets that invest in robust compliance systems, preventive maintenance, and technology will not only keep pace but also stand out as essential partners in international trade.

Frequently Asked Questions (FAQs)

-

What is intermodal trucking?

Intermodal trucking involves the use of trucks to transport shipping containers between various modes of transportation, including ships, trains, warehouses, and customer locations. It connects global shipping networks to local delivery.

-

How does intermodal trucking differ from over-the-road trucking?

Intermodal trucking typically involves shorter, more frequent trips between ports, terminals, and distribution centers. In contrast, over-the-road trucking encompasses longer hauls across states or regions.

-

What are the main benefits of intermodal trucking?

It lowers costs by reducing long-haul trucking, reducing driver fatigue, supporting greener logistics, and providing access to broader markets through port and rail connections.

-

What are the challenges in intermodal trucking?

Challenges include congestion at ports, limited chassis availability, complex scheduling with multiple carriers, and strict regulatory requirements.

-

Why is compliance important in intermodal trucking?

Compliance ensures trucks are road-ready and drivers meet safety and Hours of Service regulations. Strong compliance protects fleets from fines, delays, and credibility risks.

-

How does technology improve intermodal trucking?

Technology enables real-time GPS visibility, automated maintenance workflows, digital compliance tracking, and analytics that help fleets plan more efficiently.

-

How does REACH support intermodal trucking operations?

REACH digitizes inspections, automates work orders, and provides real-time tracking. It ensures that trucks remain compliant, reliable, and ready to handle first- and last-mile movements in intermodal logistics.