Picture a fleet manager juggling two screens on a busy morning. On one screen, the GPS dashboard displays the location of every vehicle on the road. On the other hand, a spreadsheet lists inspection reports, service requests, and repair notes. Both systems are valuable, but they do not talk to each other.

A defect logged on paper may take hours to reach the service team. A vehicle waiting for approval sits idle longer than necessary. Meanwhile, customers continue to ask for updates that the manager cannot confidently provide. The tools are working, but the lack of integration is costing the fleet time, money, and trust.

This is not an unusual story. Many fleets run GPS tracking and fleet management separately. They have invested in devices, purchased service tools, and trained their personnel. Still, without integration, the result is a patchwork system full of gaps.

This guide, presented through a case study lens, reveals what truly happens when GPS tracking and fleet management operate in silos, the costs that fleets incur as a result, and the transformation that occurs when both are integrated. It also demonstrates why REACH is the platform that makes this integration practical and profitable in 2026.

Key Takeaways

- GPS tracking and fleet management deliver partial value when used separately.

- Disconnected systems create inefficiency, downtime, and compliance risks.

- Integrated systems tie GPS data to inspections, service, and compliance workflows.

- Integration builds customer trust through accurate ETAs and transparency.

- REACH provides seamless integration that turns data into uptime, compliance, and ROI.

A Fleet Without Integration

Consider a logistics company with 150 vehicles spread across regional routes. They use GPS trackers to monitor location, and they have a separate system for logging inspections and service records. On paper, they have the right tools in place.

However, when a driver completes a daily inspection and notes a brake issue, the information does not automatically flow to the service team. Instead, it is logged manually and sent later through email or paper forms. The vehicle appears on the GPS map as “active,” but in reality, it should not be on the road until repairs are made.

Meanwhile, the service manager is unaware of the defect until hours later. By the time a work order is created, the vehicle has already lost valuable operational time. Dispatchers cannot see that the truck is out of service, so they schedule it for deliveries, leading to last-minute cancellations and frustrated customers.

The GPS device is functioning properly. The service system is doing its job. Yet because they are not integrated, the fleet wastes hours, risks compliance penalties, and loses credibility with customers.

This is the reality for many fleets in 2026: good technology, working in silos, delivering partial visibility but no real control.

The Cost of Disconnection

Running GPS tracking and fleet management as separate systems might seem manageable at first, but the hidden costs quickly add up. What appears to be two capable tools often becomes a source of inefficiency, risk, and unnecessary expense.

Lost Time in Administration

Without integration, managers spend hours reconciling data across dashboards, spreadsheets, and paper records. A defect logged during an inspection must be manually entered into the service system. GPS updates show location but not vehicle status, forcing managers to double-check records before making decisions. Each small delay compounds into hours of lost productivity every week.

Longer Vehicle Downtime

Disconnected systems slow down the process of turning inspection results into service action. A defect that should trigger an immediate repair often remains idle until someone manually inputs it into the correct system. Vehicles spend longer in the yard waiting for approval and repair, which reduces fleet availability and squeezes delivery schedules.

Compliance Gaps and Audit Risk

When inspections and GPS tracking live separately, compliance records are vulnerable. Reports get misplaced, not tied to specific vehicle histories, or delayed in reaching the right team. If regulators request proof of inspections or DVIRs, the fleet risks penalties or even having vehicles pulled because records are incomplete or inconsistent.

Frustrated Customers

Customers notice when fleets are not reliable. Without integration, dispatchers may promise deliveries using vehicles that are actually out of service. Delays, cancellations, and vague updates damage trust. Over time, these missteps can erode customer relationships and result in lost contracts.

Financial Drain

All of these issues translate into measurable costs:

- Overtime spent on manual admin.

- Revenue is lost when vehicles sit idle for longer than necessary.

- Fines from compliance shortfalls.

- Contract losses from poor service reliability.

In our case study, the fleet has the right technology; however, because the systems are disconnected, it is effectively running with blind spots. Instead of solving problems, the tools create new ones.

What Happens When Systems Are Integrated

Now imagine the same logistics company, but with GPS tracking and fleet management fully integrated. Instead of separate systems, every data point flows into one platform that connects location, inspections, service, and compliance. The difference is immediate.

Defects Trigger Instant Action

A driver logs a brake defect during the morning inspection. Instead of waiting for paperwork or manual entry, the inspection is captured digitally and tied directly to the vehicle’s GPS profile. The system flags the issue instantly, and a service request is created. The service manager sees the alert in real time and assigns the repair without delay.

Downtime Shrinks

With the defect already logged and tracked, the vehicle is serviced quickly. Managers can monitor progress from their dashboard and know exactly when the vehicle will be road-ready. Downtime is reduced from hours or days to a predictable, shorter window. Vehicles return to operation more quickly, and schedules remain intact.

Dispatch Gains Real Visibility

In the GPS dashboard, dispatchers now see more than just location. They can view service status and compliance readiness alongside movement data. Instead of mistakenly scheduling a vehicle that is in the shop, they reroute assignments to available trucks. The result is smoother operations and fewer last-minute cancellations.

Compliance is Always Audit-Ready

Every inspection, defect, and service record is tied to GPS data in one unified history. When regulators request proof, managers can provide complete, timestamped records with just a few clicks. Compliance becomes less about scrambling for documents and more about confidence in being prepared.

Customers See the Difference

Customers no longer get vague answers about deliveries. Instead, they receive accurate ETAs backed by real-time GPS data and the assurance that vehicles are safe and compliant. Transparency strengthens trust, making the fleet a more reliable partner in the supply chain.

The Turnaround

For this fleet, integration transforms the same devices and tools from a patchwork system into a unified operation. The change is not in buying more technology, but in connecting what already exists. This is the power of integration: visibility that leads to action, not just information.

Benefits of Integration in Practice

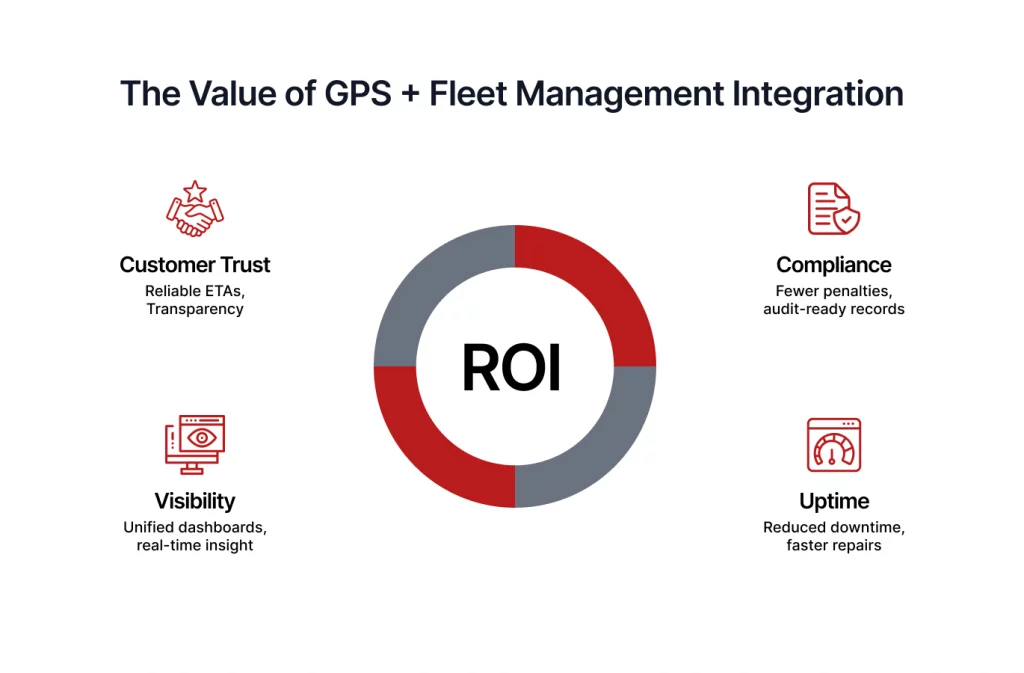

The case study makes it clear: when GPS tracking and fleet management systems operate in silos, fleets struggle to operate effectively. When they are integrated, operations undergo significant changes. The shift is not just theoretical. It delivers measurable benefits across compliance, uptime, visibility, and customer trust.

Compliance Confidence

Integration ensures that every inspection, defect, and service record is tied directly to GPS data. Managers no longer chase paper logs or risk missing documentation. Instead, they can generate audit-ready reports in seconds. Compliance becomes an integral part of daily operations, rather than a last-minute effort before inspections.

Reduced Downtime

With defects triggering service events automatically, downtime shrinks. Vehicles spend less time waiting in yards and more time on the road. This reduces the strain on dispatch, maintains consistent schedules, and improves asset utilization. For fleets, even a small reduction in downtime adds up to significant annual savings.

Unified Visibility

Managers no longer need multiple dashboards. Integration combines GPS location, service progress, and compliance status into a single view. This unified visibility means fewer blind spots, fewer errors, and faster decision-making. Dispatchers can reroute with confidence, and service managers can prioritize repairs in real time.

Stronger Customer Trust

Transparency has become a deciding factor in logistics contracts. With integration, customers receive accurate ETAs and delivery updates backed by real data. Fleets gain a reputation for reliability, which leads to stronger retention and more growth opportunities.

Tangible ROI

When you combine fewer compliance penalties, shorter downtime, reduced admin labor, and stronger customer relationships, the financial return becomes clear. Integration is not just a technical improvement. It is a business decision that pays off across the balance sheet.

The Value of Integration

How REACH Delivers Seamless Integration

The case study demonstrates the benefits that fleets gain when GPS tracking and fleet management are integrated. But making that integration possible requires the right platform. Many systems promise visibility yet fail to connect the dots between devices, compliance, and service. REACH is designed to close those gaps and deliver integration in practice, not just in theory.

Hardware Agnostic, Fleet Ready

REACH is not locked to a single type of device. Whether a fleet uses plug-and-play OBD units, hardwired devices for high-value assets, or solar-powered trackers for trailers, REACH consolidates the data into a single platform. This flexibility enables fleets to select the hardware that best suits their assets and budgets, without concern for compatibility.

Compliance Built Into the Workflow

Where most systems stop at location, REACH ties GPS data directly to inspection records and DVIRs. Every defect logged is automatically linked to a vehicle’s profile and tracked throughout the repair process. Compliance records are stored digitally, timestamped, and always ready for audits. Integration makes compliance a routine process, rather than a reactive one.

Service Digitization for Uptime

Downtime costs fleets money every hour. REACH reduces that impact by converting GPS and inspection data into service events the moment an issue is flagged. Managers can track repair progress in real time, cutting delays and keeping more vehicles on the road. This direct connection between tracking and service is what transforms efficiency.

Dashboards That Focus on What Matters

Integration is only useful if the data is clear and actionable. REACH’s dashboards combine location, service, and compliance status into one view. Instead of flipping between screens, managers see exactly which vehicles are road-ready, which need attention, and how schedules should be adjusted.

Designed for Practical ROI

Some platforms overwhelm fleets with features that add complexity without impact. REACH maintains its focus on outcomes, including compliance confidence, reduced downtime, and customer trust. By aligning technology with real-world priorities, it delivers a return on investment that goes beyond location tracking.

The Turning Point in the Case Study

For the logistics fleet in our story, REACH is the system that transforms fragmented tools into a unified operation. GPS data no longer sits in isolation. It flows directly into inspections, service events, and customer updates. Vehicles return to service more quickly, audits become less stressful, and customers remain loyal.

Integration is no longer a challenge. With REACH, it becomes the foundation of how the fleet operates in 2026.

Integration as the New Standard

The case study shows what many fleets already experience. GPS tracking alone provides location, while fleet management systems handle inspections and service. When these tools remain disconnected, downtime stretches, compliance gaps appear, and customers lose confidence. The cost of disconnection is measured not just in money but in trust and reputation.

Integration changes everything. When GPS and fleet management are integrated into a single platform, defects trigger service instantly, compliance is always audit-ready, and managers make faster, clearer decisions. Vehicles spend more time on the road, customers get reliable updates, and fleets protect both profitability and credibility.

This is the role REACH plays in 2026. By combining hardware flexibility with compliance-first workflows and service digitization, it ensures that integration is not a challenge, but a competitive advantage. For fleets under pressure to deliver more with fewer resources, integration is no longer optional. With REACH, it becomes the new standard.

Frequently Asked Questions (FAQ)

-

What does integration mean in fleet management?

Integration means GPS tracking and fleet management systems work together as one. Location data flows directly into inspections, service workflows, and compliance records, giving managers a unified view instead of fragmented dashboards.

-

Why is GPS and fleet management integration important?

Without integration, fleets waste time reconciling data, vehicles spend more time in downtime, and compliance gaps emerge. Integration connects GPS with service and compliance workflows, reducing delays and keeping fleets audit-ready.

-

What problems come from disconnected systems?

Disconnected systems lead to duplicate data entry, longer repair cycles, and compliance gaps. Dispatchers may schedule vehicles that are not road-ready, causing missed deliveries and frustrated customers.

-

What benefits do fleets see with integration?

Fleets gain compliance confidence, faster service turnaround, unified dashboards, and stronger customer trust. Integration also creates tangible ROI by reducing fines, wasted labor, and downtime costs.

-

How does REACH enable integration?

REACH is hardware agnostic and connects GPS device data directly into compliance and service workflows. DVIRs, inspections, and service events are all integrated with GPS in a single platform, reducing downtime and ensuring audit readiness.

-

How does integration improve customer relationships?

Integrated systems provide accurate ETAs and transparent updates backed by real-time data. Customers gain confidence that deliveries are reliable, vehicles are compliant, and fleets are accountable.